Introduction

If you want to create a line of cosmetic products, there are many tasks you need to perform, such as making a list of ingredients, creating formulations, and then testing the product.

But the most important step is choosing the best packaging for your cosmetic products.

The reason is that packaging is the first thing that catches the attention of potential customers.

And we know that it is very important to make a good impression on your customers and clients.

In this article, we are going to discuss what you want to know about cosmetic packaging especially packaging materials.

We believe that most of your problems with cosmetic packaging can be solved after reading this blog.

Table of Content:

1.Outer packaging

2.Inner packaging

3.Product packaging

3.1 Glass

3.2 Plastic

3.3 Aluminum

3.4 Paper

3.5 Bamboo

4.Nine key considerations for cosmetic packaging

5.How to choose eco-friendly cosmetic packaging materials

6.The latest cosmetic packaging design trends

When it comes to packaging, we usually think of three different layers: the outer packaging, the inner packaging, and the product packaging.

Outer packaging

The outer packaging is the shipping box or mailer box in which your cosmetic products are packed to be delivered or the bag in which they are packed at the checkout in a shop.The main purpose of these outer packaging, apart from telling the customer what type of cosmetic product is contained inside, is to protect the item during transportation and ensure that its quality is not compromised.

Inner packaging

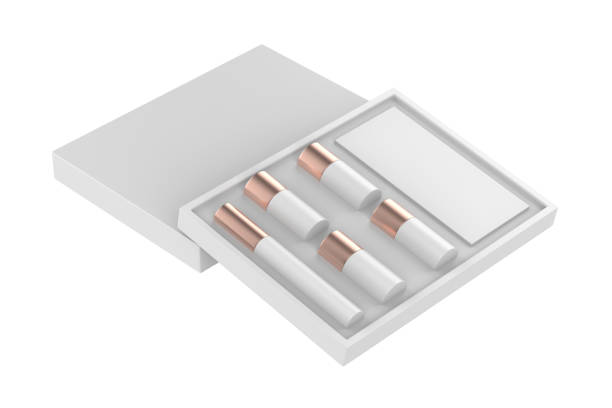

Inner packaging is packaging that holds cosmetic products and can add another layer of protection. They are typically folding cartons, sliding boxes, slide boxes, cardboard (or corrugated) boxes, or even pillow-shaped boxes. In addition, inner packaging carries important information about the product, such as ingredient compositions, instructions for use, and so on.

Related blog :A Useful Guide to Box for Cosmetic Packaging

Product packaging

Common cosmetic product packaging materials can vary depending on the product, brand, and design preferences, but there are several materials that are frequently used in the cosmetics industry. These materials are chosen for their aesthetics, functionality, and ability to preserve the product. Some common cosmetic product packaging materials include:

1. Glass

Glass is the safest material for cosmetic products.

This material is an ideal choice for products that contain different types of oils and acids.

As glass is not affected by corrosion, it can stand the test of time.

The advantages of glass

On the good side, glass is generally considered the most “natural” of the lot, both in terms of its production (low pollution) and its composition.

Indeed, the manufacture of one ton of glass requires about 700 kilos of sand, 200 kilos of limestone, and 300 kilos of various raw materials.

All these materials are found in abundance in nature.

In addition, it gives the product an elegant, even luxurious touch. For example, thick-walled glass jars are often used for creams, balms, and also eyeshadows, lip glosses, and gels.

Glass bottles and flasks are the norms for essential oils and vegetable oils.

Besides, tinted glass (amber or blue) is preferred so that the contents are protected from light and do not deteriorate.

Being easy to clean, even at high temperatures, glass containers are easily reused.

Glass is also an easily recyclable material. Throwing a glass jar or bottle into the waste garbage can has become a well-established habit for most consumers.

The disadvantages of glass

On the downside, glass is obviously a heavy and fragile material, so its eco-balance (transport and logistics) is greater than with plastic or metal.

It is also quite energy-consuming since the melting necessary for its manufacture implies reaching about 1500°C, at a rate of more than 1160 kWh /tonne of glass produced.

2. Plastic

Plastic is light, flexible, unbreakable, and hygienic, not to mention its low cost.

From an aesthetic point of view, plastics are also extremely flexible and can therefore adopt a wide variety of shapes and colors.

The plastics industry is also renewing itself to offer more and more recycled plastic containers.

It is also important to understand that not all plastics are created equal.

As such, we recommend these two types: PET (polyethylene terephthalate – number 1), and PP (polypropylene – number 5);

A PET container shipped 1,000 km away saves 19g of CO2 (carbon dioxide equivalent) compared to the same glass container.The latter, PP, is preferred because of its higher recycling rate.

We should also mention the recent appearance of PET bio-plastics, made from sugar cane.

Their use is still rare, but they should be of interest to many packaging manufacturers in the future…

Here’s a brief introduction of three common sustainable plastics options including PET,PP and HDPE.

PET

Polyethylene terephthalate looks like glass. But in reality, it is clear plastic bottles or jars. In most cases, it is used for cosmetics and beverage packaging.

Over the years, they have gained popularity because they are unbreakable, inexpensive, and lightweight.

PET is one of the best cosmetic container material because it creates a solid barrier between the product and the solution it contains.

Thus, the material does not react with the plastic. PET is a perfect choice if you want to store essential oils and alcohol.

PP

Propylene plastic is also known as PP, which is another popular packaging solution for cosmetic and skincare brands.

When it comes to strength, it’s better than PET. Some examples of these units include deodorant tubes, square lotion tubes, and hand cream jars, to name a few.

HDPE

HDPE, or high-density polyethylene, is another popular material choice for cosmetic packaging due to its durability and resistance to wear and tear.

HDPE is so versatile that it can be molded into a wide range of shapes and sizes, making it ideal for accommodating a variety of products and applications.

Additionally, HDPE is fully recyclable, making it a sustainable material choice for eco-conscious consumers.

When selecting HDPE for your cosmetic packaging needs, be sure to consider the weight and contents of your product to ensure that the material can properly support and protect your product.

The advantages of plastic

It is obviously the low cost of plastic makes itself the market leader.

It is also light, flexible, unbreakable, and hygienic.

From an aesthetic point of view, plastics are also extremely flexible and can therefore be made in a wide variety of shapes and colors.

Since the end of the 2010s, the plastics industry is also renewing itself to offer more and more containers made of recycled plastics – a good point that shows the evolution of the sector.

The disadvantages of plastic

In addition to the environmental problems of the oil from which this material is derived, a drawback of plastic is its physical stability.

It is vulnerable to absorption, stress cracking, and cracking. Its poor resistance to ink and other chemicals also limits its use for certain types of packaging.

Some plastics used in the food industry have recently been suspected of releasing toxic substances (bisphenols, phthalates…) under certain conditions of use (e.g. microwave cooking).

These phenomena of interactions between the container and the content can potentially have an impact on the quality, effectiveness, and safety of a cosmetic product.

However, they are not yet sufficiently studied in the cosmetics sector.

Moreover, plastic is not infinitely recyclable. It ends up either rejected in nature in some form or burned in sorting centers.

And there is a problem of energy consumption and potentially toxic emissions into the environment.

The application of plastics materials in cosmetic packaging

At present, the application of barrier packaging materials in cosmetic packaging is in a period of increasing use.

Commonly used domestic high-barrier materials include aluminum foil, polyvinyl alcohol (PVA), ethylene-vinyl alcohol copolymer (EVOH), nylon (PA), and polyethylene terephthalate (PET), etc. Aluminum foil, PVA, and EVOH are high-barrier materials.

Nylon, PVA, and EVOH have similar barrier properties and are medium barrier materials.

For cosmetic tube packaging products, if the product itself has high barrier properties, the following three types of barrier plastic pipes are generally used.

-ABL:

its typical structure is PE/PE+EAA/AL/PE+EAA/PE, which is made of aluminum foil and plastic film by co-extrusion and compounded into sheets and then into pipes. The main barrier is The barrier property of the aluminum foil layer mainly depends on the degree of the pinhole of aluminum foil. When the thickness of the aluminum foil increases, the barrier property increases .

-PBL:

its typical structure is PE/PE/EVOH/PE/PE, all plastic compounds, and its barrier layer is usually EVOH or oxidized PET. As the thickness of EVOH increases, the barrier is strengthened.

To get more information about ABL and PBL, please refer to this blog:

ABL vs. PBL vs. Co-Extruded Tubes: What’s Right For You

Glass or plastic: which pollutes more?

If we take into account only the basic material intensity figures (ratio between the domestic consumption of raw materials and the gross domestic product), a jar made of PET (a thermoplastic polymer) uses twice as much abiotic material (minerals and fossil fuels) and 17 times as much water (needed in its manufacturing process) as a similar jar made of glass.

To obtain 1 kilo of PET plastic, 2 kilos of oil are needed.

Thus, the amount of greenhouse gas emissions is 5 times higher for the plastic jar. In this respect, glass is the clear winner.

But beware: this result is only valid in a local system, where the pollution caused by the transport of the product is negligible.

Over long distances, the material intensity figures are multiplied by the number of kilometers traveled to transport the glass.

In this case, the glass loses out because it requires five times as much transportation due to its weight.

A PET jar shipped 1000 km away saves 19g of CO2 (carbon dioxide equivalent) compared to a glass jar.

In addition, plastics recycling is progressing.

PET is often recycled, at least in part, and can be incinerated to produce fuel.

PP (Polypropylene) plastic is even more environmentally friendly: it is just as light and fully recyclable since it can be sorted with recyclable plastics.

Related blog :Plastic Bottle vs Glass Bottle for Cosmetic Packaging

3. Aluminum

Metal cosmetic containers are most often made of aluminum, as shown by our hairspray, deodorant, shaving foam, or toothpaste.

As a barrier material, aluminum offers excellent protection against germs, UV, humidity, and temperature variations.

Aluminum bottles are therefore particularly suitable for fragile contents, being able to dissipate heat.

The advantages of aluminum

As a barrier material, aluminum offers excellent protection against germs, UV, humidity, and temperature variations.

By dissipating heat, aluminum bottles are particularly suitable for fragile contents.

Typical example: is hydrolats, whose fragrances and virtues can then be preserved.

Another advantage is that metal packaging is unbreakable and infinitely recyclable.

For companies wishing to be environmentally friendly, aluminum is an excellent choice.

It saves natural resources, even though aluminum is the most abundant metal on earth.

Particularly positive is the fact that about half of the aluminum used by industry in Australia is recycled aluminum.

Much lighter and more malleable than glass, aluminum can be shaped into a wide variety of shapes and sizes. It offers manufacturers many exclusive design possibilities, and its silvery sheen gives it a certain elegance.

The disadvantages of aluminum

The production of aluminum causes air pollution and toxic waste during the extraction and processing of the metal (e.g. red mud).

And from a practical point of view, aluminum dents at the slightest impact.

Finally, aluminum has recently criticized when it was introduced into cosmetic formulas themselves.

It is suspected of being neurotoxic and present in some deodorants and toothpaste.

But aluminum cosmetic containers are not concerned because a food-grade interior varnish always separates the container from the content, thus avoiding any risk of migration.

Blog series:The Best Guide to Aluminium Cosmetic Packaging

4. Paper

Paper has been widely used in packaging for many years as an ideal alternative to sustainable options. Paper packaging is found in various forms, the most common being paper fillers. Paper fillers are made from cardboard or recycled paper. Paper cosmetic bottles and cardboard boxes also rely on paper as their primary material and therefore have excellent environmental attributes.

The advantages of paper

Paper cosmetic packaging is a sustainable option because it is often manufactured using renewable resources, such as wood and cellulose, which helps to reduce dependence on finite resources. In addition, paper cosmetic packaging is recyclable, which means it can be recycled and reprocessed into new paper products, thereby reducing waste and resource waste. By encouraging consumers to put paper packaging into the recycling cycle, the environmental burden can be effectively reduced.

Additionally, paper cosmetic packaging is often biodegradable, which means it can degrade naturally after being discarded, leaving no long-term environmental problems. This is in stark contrast to regular plastic packaging, which usually takes hundreds of years to degrade.

In addition, manufacturing paper cosmetic packaging typically requires less energy than other materials such as glass or aluminum, helping to reduce carbon footprints and dependence on fossil fuels.

Moreover, paper cosmetic packaging is highly creative and customizable and can be printed, colored and designed to meet the needs of different brands, helping to brand and engage consumers.

Finally, well-designed paper cosmetic packaging reduces unnecessary packaging materials and lowers the weight and volume of packaging, thereby reducing energy consumption during transportation and storage.

The disadvantages of paper

Paper packaging offers advantages in many respects, but also has some limitations. However, for cosmetic products that require a high degree of water resistance, such as liquid cosmetics or bath products, paper packaging is often not sufficiently resistant and additional water-resistant packaging or materials are therefore required.In addition, paper packaging is relatively thin and may not provide sufficient physical protection, which may result in damage or deterioration of the cosmetic product during transportation and storage.

Plus, under prolonged storage conditions, paper packaging has limited durability and may be susceptible to moisture, potential physical damage or abrasion.

Finally, although paper packaging typically uses renewable resources, managing forest resources and pulp production may also have negative environmental impacts, which may lead to deforestation and ecosystem destruction if not sustainably managed.

Blog series:All About Paper Packaging You May Wonder

5.Bamboo

Bamboo cosmetic packaging has become a new trend in the beauty industry. This type of packaging is highly preferred by brands for its sustainability and affordability. Not only that, but even small business owners can now adopt this sustainable practice without spending too much money.

The advantages of bamboo

First and foremost, one of the reasons why bamboo is widely used for cosmetic packaging is its outstanding product safety. Bamboo is a material that does not react with any beauty products, chemicals or medications, ensuring that the ingredients and efficacy of the product will not be compromised.

Another important advantage of bamboo packaging is its durability. Compared to other materials such as plastic, bamboo is more durable and can be used multiple times without having to worry about the container breaking. This not only reduces packaging waste, but also extends the life of the product, in line with the principles of sustainability.

Bamboo is also favored for its sustainability. It is one of the fastest growing grasses in the world, and a mature bamboo plant can grow up to 35 inches per day, making it readily available. This makes bamboo relatively inexpensive to produce, making it a cost-effective packaging option.

Best of all, bamboo is 100% biodegradable and will naturally decompose when discarded without producing harmful toxins, thus helping to reduce reliance on harmful plastic products and reducing the risk of environmental pollution. This makes bamboo an ideal material for eco-friendly packaging, helping to reduce the negative impact on the planet.

In addition, the natural look and texture of bamboo makes bamboo cosmetic packaging very attractive in appearance. Brand logos and names can be added through engraving to give the packaging more personalization. It will add color to the product no matter where it is placed on anyone’s dresser.

The disadvantages of bamboo

First, bamboo packaging is less flexible in terms of customization than plastic or glass. Realizing complex designs or incorporating unique shapes can be challenging.

Secondly, since bamboo is sensitive to moisture, over time, moisture can cause it to expand, warp or deteriorate. So make sure to store bamboo packaging away from humid air as this will ensure a better shelf life for the product.

Also, bamboo packaging is bulkier than plastic or aluminum packaging, which may increase transportation costs and storage space requirements.Finally, it is even more important to note that the quality of bamboo may vary depending on the source and manufacturing process. Inconsistent quality may result in changes in the appearance and durability of bamboo packaging.

Nine key considerations for cosmetic packaging

Designing effective cosmetic packaging is a multifaceted task that requires careful consideration of several key factors. Not only does your packaging represent your brand, but it is an important tool for attracting and retaining customers. To ensure your cosmetic packaging stands out and resonates with your target audience, here are nine key considerations:

Target Customer Analysis:

To create packaging that resonates with your audience, it’s crucial to understand your target customers. Research their preferences, demographics and shopping habits. By doing so, you can customize your packaging to effectively meet their tastes and needs.

Brand Identity Consistency:

Your packaging should seamlessly match your brand personality. Consistency in design, color scheme and typography can help customers immediately identify your product and build a strong brand image in the marketplace.

Packaging materials and labels:

Careful selection of packaging materials not only protects your cosmetics, but also reflects your brand values. Purchase labels that convey important information about your products, such as ingredients, directions for use and safety precautions.

Regulatory compliance:

Cosmetic packaging regulations may vary from region to region. Make sure your designs comply with local, state and national guidelines. Staying up to date on these regulations is critical to preventing legal issues.

Budget planning:

Packaging can be a significant cost in product manufacturing. Avoid hasty decisions by creating a detailed budget. Considering cost-effective materials or exploring mass production options can save money in the long run while maintaining quality.

Consistency in design:

Consistency across your product line enhances brand recognition. Ensure that your packaging design elements, such as logos, color schemes, and fonts, remain uniform to enhance your brand image and make it easy to differentiate from competitors.

Transportation Considerations:

In addition to aesthetics, consider the practicality of transporting your cosmetics. Minimize the risk of product damage by choosing packaging materials that offer adequate protection during shipping. Efficient, secure packaging also saves on transportation costs and reduces environmental impact.

Packaging Flexibility:

Depending on the nature of the cosmetic product, consider packaging that is practical and easy to use. Flexible or squeezable containers may be more suitable for holding creams, gels or liquids to ensure convenience for customers.

Environmental sustainability:

As the beauty industry embraces sustainability, eco-friendly packaging has become a growing trend. Appeal to eco-conscious consumers by choosing recyclable materials, reducing unnecessary packaging, and communicating your commitment to environmental responsibility.

In short, creating impactful cosmetic packaging requires a combination of aesthetic appeal, practicality, and consistency with your brand image. By taking these factors into consideration, you can design packaging that not only appeals to customers, but also enhances your brand’s reputation in the competitive cosmetics market.

How to choose eco-friendly cosmetic packaging materials?

Choosing the right packaging materials is crucial in order to reduce your environmental impact and achieve sustainability. Different types of cosmetic products, such as liquids, gels, solids, sprays and powders, require different types of packaging to meet their needs. Various packaging materials offer different aesthetics, durability and functionality and have different uses depending on the type of product. Additionally, some products may not be compatible with certain materials, so choosing the right packaging materials is key to avoiding reformulation of your products.

To be sustainable, your packaging material choices must meet both environmental goals and business values. First and foremost, you should prioritize packaging materials that can be easily recycled and reused. However, it is important to note that different materials have different levels of recyclability. Recyclable materials are crucial in the packaging industry as they help reduce dependence on plastics and help preserve the environment. Biodegradable packaging, such as packaging made from biodegradable materials such as paper, is essential for implementing environmentally friendly packaging strategies. Once disposed of, biodegradable containers break down into soil nutrients, reducing their impact on the environment.

Refillable packaging has been shown to be a highly sustainable packaging solution. By refilling empty cosmetic bottles, solid waste generation can be reduced, helping to minimize the burden on the environment. Therefore, considering the introduction of refillable packaging in your organization is also an environmentally friendly move.

To sum up , choosing the right packaging materials for your products and business is a critical decision that can help reduce your environmental footprint and add business value at the same time. Ensure that the materials are sustainable, recyclable and environmentally friendly to achieve your sustainability goals.

The latest cosmetic packaging design trends

Cosmetic packaging design trends continue to evolve to meet changing consumer preferences and keep pace with industry innovations. Here are some of the increasingly popular cosmetic packaging design trends:

Minimalist design:

A clean and minimalist design can instantly attract consumers. It conveys a simple and clear message, making it easier for customers to understand your product at first glance. Minimalistic design focuses on essential elements to reduce clutter and distractions.

Sustainable materials:

Environmental awareness continues to grow. Consumers are increasingly aware of the environmental impact of their purchases. Using eco-friendly and sustainable materials for packaging can appeal to eco-conscious consumers. Materials such as recycled paper, biodegradable plastics and reusable containers are becoming increasingly popular.

Unique custom fonts:

Typography plays an important role in packaging design. Choosing unique and visually appealing fonts can grab the attention of your target audience. This is a creative way to convey your brand message and differentiate your product from your competitors.

Bold graphics in packaging design:

Establishing a recognizable pattern or logo for your brand can help customers quickly identify the product on store shelves. This branding technique can create a strong visual identity and enhance a company’s reputation without relying on public statements.

Travel size:

Travel size cosmetics are becoming more and more popular as many consider these products essential when traveling. Packaging that is designed to be compact, lightweight and easy to carry is critical to attracting consumers who value travel convenience.

Refillable products:

Refillable products are growing in popularity as consumers prioritize sustainability. Providing refill bags and refill stations for your cosmetics products allows customers to enjoy your products while reducing waste. This approach aligns with the environmentally friendly options many customers are looking for.

Structured layout:

Structured packaging design focuses on innovation, functionality and brand expression. Its purpose is to make your products stand out on store shelves and effectively communicate your brand values. Structured packaging can create a memorable unboxing experience for customers and leave a lasting impression.

Personalization:

Adding a personal touch to your packaging can create a strong emotional connection with your customers. Customized packaging, such as including the customer’s name or a personalized message, can enhance the overall experience and make your brand more memorable.

Interactive packaging:

Interactive elements such as QR codes or augmented reality features can engage customers and provide additional information about your products. This innovative approach can make your brand stand out in the highly competitive cosmetics market.

Inclusion:

Diversity and inclusion in packaging design are becoming increasingly important. Representing a variety of colours, genders and backgrounds on packaging can resonate with a wider audience and promote inclusivity.

Conclusion

In conclusion, as we explored above, cosmetic packaging is complex and ever-changing. From the importance of the outer and inner packaging to the variety of materials available such as glass, plastic, aluminum, paper and bamboo, your choices can have a significant impact on the aesthetics and environmental impact of your product.

We also summarize the nine key considerations for successful cosmetics packaging, emphasizing the balance between functionality, aesthetics and sustainability.

Finally, we also discuss the latest design trends shaping the future of cosmetics packaging. In the dynamic packaging industry, staying informed and making smart choices is crucial for businesses and consumers alike. By utilizing eco-friendly materials and innovative design, we can create cosmetic packaging that is more sustainable and visually appealing.

We hope that this article will give you a more in-depth and professional understanding of cosmetic packaging, especially packaging materials.

If you have any further questions or require tailored solutions for your cosmetic products, please don’t hesitate to reach out. We’re here to help you find the perfect packaging that aligns with your specific requirements. Contact us today and let Primepac be your trusted partner for cosmetic packaging.