Beverage and food packaging materials are the industries that waste the most energy and resources. The annual production demand for packaging materials is as high as 67 million tons, which not only consumes energy resources but most poses a serious threat to the ecological environment. In order to better protect the environment, therefore, biodegradable packaging came into being.

Degradable plastic refers to plastics with a certain of additives (such as starch, modified starch or other cellulose, photosensitizers, degradants, etc.), which have lower stability and are more easily degraded in the natural environment. Its application can effectively alleviate ecological and environmental problems and reduce the waste of resources.

After this article gives an overview of the biodegradable packaging market, it mainly explains the types of degradable packaging materials and summarizes the factors driving this market development, and then describes the current market size and forecasts of the market’s future. Finally, it points out various challenges encountered by the degradable packaging industry in the development process.

Market review of biodegradable packaging

Companies around the world are adopting sustainable packaging solutions, including the use of biodegradable and recyclable paper. According to statistics, paper packaging solutions will dominate the market in 2021, so the use of paper in packaging materials will increase. Many companies that provide paper packaging solutions focus on biodegradable products to attract consumers. Industry leaders are working to provide complete biodegradable packaging solutions to gain an expanding market.

Compared to end-user consumers, the demand for these packaging solutions is considered high in the industry because it eliminates the need for attractive packaging in industrial solutions. Overall, the market is expected to show strong growth over the forecast period. However, recycling remains one of the main trends observed in the industry.

Although paper products are biodegradable, the process has been determined to be inconsistent in landfills due to the presence of external elements. The impact of the landfill is attracting the attention of municipalities. Therefore, as there are no added artificial elements, governments and organizations are promoting the recycling of disposable landfills, and biodegradable packaging is highly recyclable.

The ability to use biodegradable materials in the packaging industry is increasing due to the growing demand for recyclable materials in end-use industries such as personal and home care, food and beverage, and pharmaceuticals. This phenomenon, in particular, is supported by growing consumer awareness of their interests. In particular, in the food packaging industry, biodegradable packaging materials have been widely used to promote green living around the world, essentially by reducing waste. Several regional and global regulations to reduce ecological damage from overflowing landfills provide an amazing incentive to adopt biodegradable packaging materials. In addition, in recent decades, continuous efforts to adopt sustainability in sustainable development have led to widespread demand for such packaging materials.

Biodegradable packaging material types

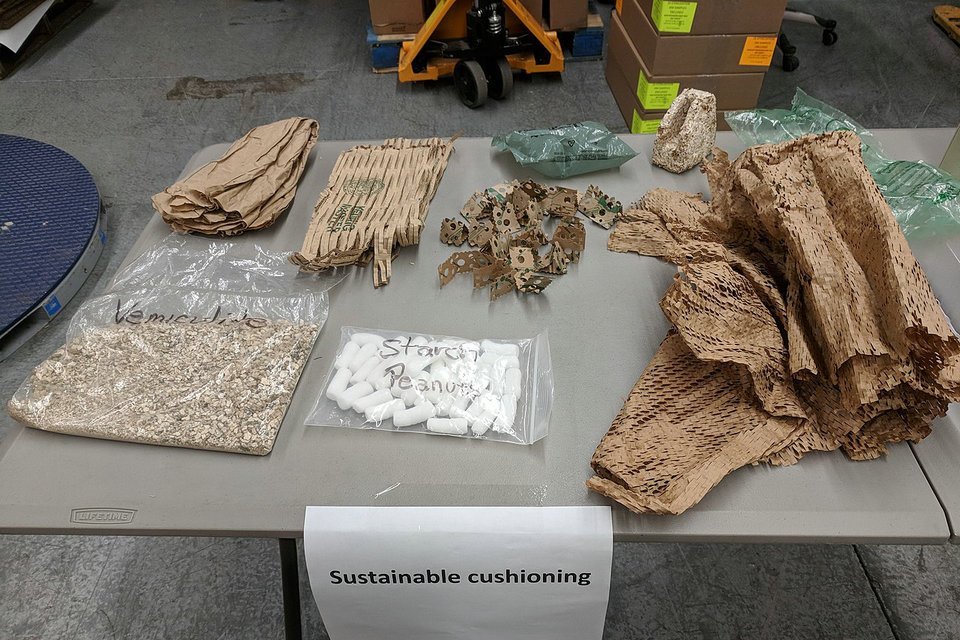

Traditional packaging materials include paper, cardboard, plastic, metal, glass, wood, and other materials. Green packaging materials mainly refer to materials that have good use performance, or function, have little pollution to the ecological environment, are easily degradable, easy to recycle, have high recycling rates, or can be effectively recycled in the environment without causing harm to human bodies.

The biodegradable packaging market was valued at $3.97 billion in 2018 and is expected to reach a market value of $10.3 billion by 2024, with a CAGR of 17.04% during the forecast period from 2020 to 2024.

Biodegradable packaging has been widely used in the packaging industry because of its ecological friendliness. With the rising price of crude oil and issues related to petroleum-based plastics (such as disposal and effective waste management), the concept of using biodegradable plastics as an alternative to various applications such as FMCG, hospital, manufacturing is increasing, which is driving the development of the market.

The key point of green packaging is whether the packaging materials are reusable and degradable. Biodegradable materials such as bioplastics and paper are widely used in the packaging industry because of their sustainable properties, appearance, and properties.

Biodegradable packaging is different from traditional non-biodegradable packaging in terms of raw materials, production technology, applications, and composting. Biodegradable packaging materials are used for all levels of packaging, such as primary, secondary, and tertiary packaging

1.Driven by sustainable development

Degradable materials have less impact on the environment, meet the requirements of sustainable development, and can effectively solve problems such as environmental crises. Therefore, the demand is constantly growing, and biodegradable packaging products are increasingly used in various industries. Since most of the materials used in this package are natural and can be degraded without a catalyst, this package has a wide range of applications in the food and beverage industry.

Many industries and governments have taken steps to reduce material waste and reduce their environmental impact. Companies such as Unilever and P & G have promised to switch to natural packaging solutions and reduce their ecological footprint (mainly carbon emissions) by 50%, which is one of the factors driving the use of biodegradable packaging in various industries. More and more innovations, such as automatic and smart packaging solutions in the industry, are being extended to end products.

2. Consumer preference driven

One of the key factors contributing to the growth of this market is the consumer increasingly focus on environmentally friendly packaging. As consumers’ focus shifts to a healthier life, consumers are more inclined to choose environmentally friendly plastic bags and environmentally friendly food packaging bags, and their demand for natural, environmentally friendly and green products is also increasing. This shift in consumer behavior is forcing major plastics manufacturers and packaging manufacturers to continually explore the possibilities for the application of biodegradable polymer materials.