Everything you

need to know

about Kraft

paper

packaging

With the ever-growing awareness of environmental issues among the population, consumers are increasingly turning their loyalties to eco-conscious businesses and products, with one of those products being kraft paper packaging. With more and more plastic restrictions being put in place around Australia, from straws to plastic bags, these eco-friendly measures have had strong support from people!

One of the trends growing is the use of Kraft paper packaging as a more and more popular packaging method, what effect does it have on the environment? What made it a popular packaging method for both businesses & consumers? In this article, we are going to learn more about Kraft paper packaging and sustainable bags.

What is kraft paper packaging?

Kraft paper bag structure: Kraft paper bag is a composite material or pure kraft paper packaging container, non-toxic, odorless, pollution-free, low-carbon environmental protection, meets national environmental protection standards, has high strength, high environmental protection, is currently the most popular in the world one of the environmentally friendly packaging materials.

Kraft paper bag is based on the whole wood pulp paper. The color of the kraft paper packaging is divided into white kraft paper and yellow kraft paper. PP film can be applied on paper to play a waterproof role. The strength of the bag can be made from one to six layers according to customer requirements. , Printing and bag-making integration. Opening and back cover methods are divided into heat seal, paper seal, and paste bottom. Scope of application is generally: chemical raw materials, food, pharmaceutical additives, building materials, supermarket shopping, clothing, and other industries suitable for kraft paper packaging industry.

Kraft paper can be classified by different factors.

The different colors: original-color kraft paper, red kraft paper, white kraft paper, flat kraft paper, single-light kraft paper, two-color kraft paper, etc.

The different applications: packaging kraft paper, waterproof kraft paper, moisture-proof kraft paper, rust-proof kraft paper, plate kraft paper, process kraft paper, insulating kraft paper board, kraft sticker paper, etc.

The different materials: recycled kraft paper, kraft core paper, kraft original paper, rough kraft paper, kraft wax paper, wood pulp kraft paper, composite kraft paper, etc.

Where did the word ‘Kraft” come from?

Kraft paper is a packaging material that gets its name from the Kraft pulping process, pioneered by Carl F. Dahl of Germany in the 1880s.

Normally, in the manufacture of paper, wood is ‘pulped’ (ground to a pulp) first, but Dahl found that treating the cellulose pulp with certain chemicals (sulfates) increased the strength of the paper. He called his paper Kraft paper – Kraft in German means ‘strength’.

This is why this type of material was eventually used as a packaging material due to its durable and useful nature in kraft paper packaging.

When it comes to kraft paper packaging, you must have heard of sustainable packaging!

Kraft packaging is one of sustainable packaging, so what other styles are there in sustainable packaging? First, let’s see what is sustainable packaging

What is sustainable packaging?

Sustainable packaging is the development and use of packaging that can improve sustainability. This involves increasing the use of life cycle inventory (LCI) and life cycle assessment (LCA) to help guide the use of packaging, thereby reducing environmental impact and ecological footprint. It includes the entire supply chain: from basic functions to marketing, to retirement (LCA) and rebirth. In addition, the ecological cost-to-value ratio may be a useful goal to improve the long-term viability and quality of life of humans and the longevity of natural ecosystems. Sustainable packaging must meet current functional and economic needs without affecting the ability of future generations to meet their needs. Sustainability is not necessarily the end state, but a continuous improvement process.

We all know that sustainable packaging is a relatively new addition to packaging environmental considerations. It requires more analysis and documentation to look at packaging design, material selection, processing, and life cycle. This is not just a vague “green movement” that many businesses and companies have been trying to include over the past few years. Companies implementing these environmental initiatives are reducing their carbon footprint, using more recycled materials, and reusing more packaging components. They often encourage suppliers, contract packers, and distributors to do the same.

How is Kraft paper made?

The production process of kraft paper involves several steps:

Pulping

The process starts by breaking down wood chips into small fibers. The wood fibers are then mixed with chemicals such as sodium hydroxide and sodium sulfide in a large vessel called a digester.

Bleaching

If the paper needs to be bleached to a lighter color, the pulp is sent through a series of chemical treatments using chlorine dioxide, hydrogen peroxide, or oxygen.

This step removes any residual lignin and produces a white color.

Washing

After the pulp has been digested and bleached, it is washed to remove any remaining chemicals.

Refining

The pulp is then sent through a refining machine to improve its strength and create a uniform texture.

Forming: The pulp is then formed into sheets by being passed through a machine that spreads it onto a large flat screen.

Drying

Finally, the sheets are dried to remove any remaining moisture and create the finished product.

As for the safety of kraft paper, the chemicals used in the pulping and bleaching process are generally considered safe and do not pose a significant risk to human health.

The production process is tightly regulated to ensure that any residual chemicals are removed during the washing and drying process.

Additionally, kraft paper is a non-toxic and biodegradable material, making it a popular choice for eco-conscious consumers and businesses.

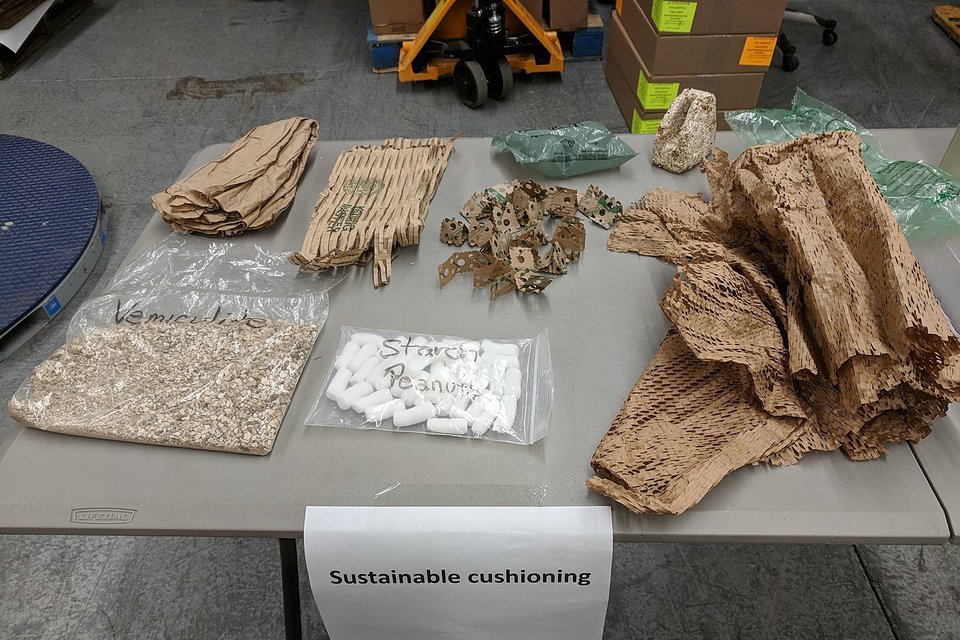

Different elements of sustainable packaging to consider

What are the types of sustainable packaging? In addition to the kraft paper, you must have seen the following types.

SUSTAINABLE PACKAGING

Kraft

Kraft paper is 100% sustainable, and among one of the most popular packaging materials in the world. It is much more sustainable to manufacture kraft paper compared to regular paper. Kraft is produced from all-natural ingredients such as pulp from all types of wood, while regular paper uses specific woods.

Bleaching is also not involved, which maintains the strength of the paper and decreases manufacturing costs. Kraft paper is also a lightweight packaging material that helps maintain a low shipping cost.

SUSTAINABLE PACKAGING

Molded pulp

Kraft paper is 100% sustainable, and among one of the most popular packaging materials in the world. It is much more sustainable to manufacture kraft paper compared to regular paper. Kraft is produced from all-natural ingredients such as pulp from all types of wood, while regular paper uses specific woods.

Bleaching is also not involved, which maintains the strength of the paper and decreases manufacturing costs. Kraft paper is also a lightweight packaging material that helps maintain a low shipping cost.

SUSTAINABLE PACKAGING

Foams packaging

A very large part of the packaging industry is the use of foams. Packaging foams are materials used in different levels of the industry. It is used as a duo-purpose protective layer, as well as to organize small products to provide a good presentation. But, foams were not always the most environmentally friendly.

As the subject of sustainable packaging continues to rise, biodegradable and paper foam alternatives have been developed to replace this material. Since the market for sustainability is growing, it is beneficial for smaller companies to ride the momentum.

SUSTAINABLE PACKAGING

Inks in packaging

The use of sustainable inks is a rising trend. These links no longer need heavy metals like lead and mercury. The biggest difference is the reduction or complete removal of volatile organic compounds. These compounds produce gases that are hazardous to both the environment, and human health.

Although energy-saving initiatives are in place, biodegradable inks have been the most impactful. These inks use organic vegetable oils. The result is a reduced impact on the environment and allows lower energy consumption during the recycling process in kraft paper packaging.

All Types of Recycled Packaging Materials

Recycled Paper Packaging

Corrugated Cardboard

Corrugated cardboard is a type of recycled paper that is made from layers of kraft paper.

It is often used for shipping boxes and other packaging applications, as it is strong and durable.

Corrugated cardboard is biodegradable and can be recycled multiple times.

Recycled Paperboard

Recycled paperboard is a type of paper that is made from recycled fibers. It is often used for packaging products such as cereal boxes, shoe boxes, and gift boxes.

Recycled paperboard is lightweight and can be recycled multiple times.

Bagasse Paper

Bagasse paper is a type of recycled paper that is made from sugarcane fibers. It is often used for food packaging, as it is resistant to grease and oil. Bagasse paper is biodegradable and can be composted.

Tyvek paper

Made from high-density polyethylene fibers, this type of paper is durable and water-resistant. It is often used for shipping envelopes and packaging for electronics. It can be recycled through special programs.

Newsprint paper

Made from recycled fibers and often used for wrapping and cushioning products. It is lightweight and absorbs shock well.

Other Recycled Materials for Packaging

Bioplastics

Bioplastics are a type of plastic that is made from renewable resources such as cornstarch or sugarcane.

They are biodegradable and compostable, making them a sustainable alternative to traditional plastic packaging.

Glass

Glass is a recyclable and sustainable material that can be used for a variety of packaging applications, including bottles, jars, and containers.

It is durable, non-toxic, and can be recycled endlessly without losing quality.

Metal

Metal packaging, such as aluminum cans, is recyclable and can be used for a variety of food and beverage products.

It is lightweight, durable, and can be recycled an infinite number of times.

Biodegradable Plastics

Biodegradable plastics are made from materials that will break down over time, such as cornstarch or potato starch.

They are not always recyclable, but they are a good alternative to traditional plastics that take centuries to decompose in the environment.

How many types of kraft paper are there?

1: According to the material can be divided into:

- Pure kraft paper bags;

- Paper-aluminum composite kraft paper bag

- woven bag composite kraft paper bag

3:According to the bag type, it can be divided into:

- Three sides sealed kraft paper bag;

- Side organ kraft paper bag;

- Free standing kraft paper bag;

- Kraft paper bag with zipper;

- Freestanding zip kraft paper bag.

3:According to the appearance of the bag type, it can be divided into:

- square bottom bag;

- seam bottom bag;

- valve pocket;

6 types of kraft paper and their best business uses

Virgin Natural Kraft Paper

Virgin natural kraft paper is the heavy lifter of the paper world. Its clean and durable fiber content and its low cost make it an ideal option for heavy-duty applications that require a high level of tear resistance. Plus, it’s perfect for printing as well, so it’s a natural for branded packaging and protective layering, wrapping, pallet interleaving, carrier sheets, and dunnage.

Natural Recycled Kraft Paper

Although not as strong and tear-resistant as virgin natural kraft, natural recycled kraft paper is a more environmentally friendly option, and still carries enough strength to do an excellent job with dunnage and void fill applications, as liners for trays and boxes, interleavers, and bottom wrap for newspapers. Both virgin and recycled kraft paper come standard in weights from 30# to 70#.

Black Kraft Paper

The most common use of black kraft paper is as a dark, durable backing for picture frames, but that’s not its only use. Black kraft paper is also perfect for fun and interesting craft projects, or as an aid to unique decorating where light barriers and dark borders are needed.

Colored Kraft Paper

Colored kraft paper is available in just about every color of the rainbow. Its vibrant hues make it perfect for all manner of craft projects, as well as fun backings for bulletin boards, standard school supplies, scrapbooking, and similar applications. If your target market includes, schools, daycares, or busy parents, colored kraft paper should be on your list.

White or Bleached Kraft Paper

Similar to virgin natural kraft in strength and durability, white or bleached kraft paper makes an especially powerful impact when a crisp, clean appearance is desired. For example, many restaurants like to use white kraft paper as an attractive and economical alternative to linen tablecloths. It also serves well for wrapping and can stand up well to the standard wear and tear a package may receive.

Printed Kraft Paper

Many different industries take advantage of the versatility and value of custom printed kraft paper for creating branded wrapping, packaging, and in-store displays. For example, a deli may order a supply of kraft paper sheets in the perfect size for wrapping sandwiches and have the deli logo and contact information printed on one side as a means of affordable, continual advertising. Many fashion manufacturers ship their garments out with printed kraft paper sleeves or sheets between individual articles, or wrapping the inside of a shoebox, again with branded logos and other information prominently displayed in kraft paper packaging.

Different Colors of Kraft Paper

The color of kraft paper can vary depending on several factors, including the type of wood pulp used, the chemical treatment process, and the degree of processing involved in manufacturing the paper.

The natural color of kraft paper is light brown, which comes from the wood pulp used to make it.

However, the color can be altered during the pulping process by adding certain chemicals, such as sodium sulfide or sodium hydroxide.

The addition of these chemicals can help to break down the lignin and remove impurities, resulting in a brighter and whiter paper.

On the other hand, unbleached kraft paper is a darker shade of brown due to the absence of chemical bleaching agents.

This type of kraft paper is often used for packaging products that require a more natural and eco-friendly appearance.

The color of kraft paper can also be affected by the degree of processing involved in manufacturing it.

For example, recycled kraft paper may have a slightly darker hue than virgin kraft paper due to the presence of residual ink and other impurities.

In terms of the impact of color on kraft paper, it generally does not affect the performance or durability of the paper itself.

However, certain colors may be more aesthetically appealing for specific packaging applications or brand identities.

For instance, darker shades of kraft paper are often used for rustic and natural-looking packaging, while brighter shades may be used for more vibrant and colorful designs.

Cost

The cost of packaging adds to the final cost of any product, which ultimately affects how your product will compete with the rest of the market. Kraft paper packaging is less expensive than plastic packaging. It also weighs less than packaging products that include features like zip closures. The weight of the packaging determines the cost of shipping, which also affects the final consumer price in kraft paper packaging.

Strength

Kraft paper is durable enough to withstand elaborate printing in modern, high-tech machinery. This means you have endless options when it comes to designing your packaging’s printing. It also holds up to shipping and shelf life very well.

Environmental Impact

Both paper and plastic are easily recyclable, but paper has an environmental edge because it also quickly decomposes if it’s thrown away instead of recycled. Therefore, you don’t have to depend on the consumer to make a good environmental choice; kraft paper is environmentally low-impact whether it’s recycled or sent to a landfill.

First and foremost, kraft paper packaging is stronger, due to its reduced lignin content and high sulfur ratio. It also doesn’t involve extensive bleaching, which decreases the paper’s strength and increases manufacturing costs.

Since it doesn’t add much weight to the package, using kraft wrapping paper keeps shipping costs down. • Its coarse texture, durability, and flexibility provide more protection.

For Your brand image

Use Kraft paper for eco-friendly business cards. • The natural quality gives business cards a look that is simple and universally appealing. • Potential clients will appreciate your environmentally conscious stance and view it as a credit to your character. • Your cards will garner attention due to their unique look.

Conclusion

After we know so much about kraft paper packaging, let’s summarize the advantages of kraft paper!

Recyclable

Most of the paper packaging that is available in the stores is recyclable.

Recycling paper packaging is more comfortable than plastic packaging.

Even some types of paper are used for the packaging can get into their original form after recycling it again and again.

Good Printing Performance

The kraft paper packaging is considered best to give an excellent printing performance.

As compared to plastic packaging the kraft paper packaging can provide impressive printing results.

Durable material & Saves space

Kraft paper packaging with a window relative to the width of the wear rate is relatively low, can be stored for a long time, after a long time will not decay, easy to save. Kraft paper boxes can be folded at Will and can occupy fewer places.

Why choose Primepac

PrimePac – based on Australian which was specializes in packaging production and design. In the area of kraft packaging industry, there are more unique technological advantages:

1 . Compared with custom pouch products, PrimePac can provide stock pouch products

2 . Print this directly on kraft paper. Compared to many kraft papers, only simple text and artwork can be printed. Primepac can print high-resolution CMYK patterns.

3 . Compared with many brown kraft paper / white kraft paper, PrimePac has more choices. We have made five kinds of paper materials, brown kraft paper / white kraft paper / cotton paper / yunlong paper / coated paper, which will also meet customer needs in the future and make more Many other attempts.

4 . Degradable technology, because the degradable film can not reach the performance of commonly used plastic film, primepac’s degradable packaging materials are basically in the form of kraft paper composite degradable film.

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.