Introduction to fast food packaging

We have introduced the types of food packaging in the previous article.

We all love fast food which we love relishing may be on a cheat day or any lazy carving day. There is one thing which is very common in all food branding is whenever you check out its surroundings and overall emotion, it does generate hunger. We feel like visiting it and indulging in hot fresh pizza, burgers, noodles, or any fast food.

As for fast food, what packaging do people generally use now?

In general, fast food packaging has the following types:

1. Disposable foam plastic packaging

2.PP plastic packaging

3.Paper fast food packaging

4.Biodegradable packaging

Down below we will go into these fast food packaging types, their advantages/disadvantages, and when to use them.

Disposable foam fast food packaging

Disposable foam fast food packaging is mainly used in these types of packaging:

Disposable foam lunch box

Disposable foam bowl

We have introduced the types of food packaging in the previous article. However, for fast food, what packaging do people generally use now?

The main component of disposable foamed fast food packaging has two main components: PP polypropylene and PS polystyrene. It is insulated, pressure-resistant, and cheap which means it is used widely. However, this approach has its own problems, also known as white pollution.

About the white pollution

White pollution is the negative effect caused by plastic rubbish. Disposable foam packaging is one of the pollution sources. The rest are plastic bags, plastic cups, and other plastic materials.

Australian policies on white pollution

In Australia, the government is working with states, territories, and industries to reduce the amount of plastic waste, increase recycling, and minimize the impact on the environment. The behavior will be an action like supporting the industry in designing more sustainable solutions and recycling materials before they enter the environment to reduce waste and garbage.

However, the government also joined forces with businesses to develop plans and guidelines to prevent plastic waste from entering the ocean. At the same time, it also encourages support and encourages the reduction of plastic waste and garbage.

Hazards of disposable foam fast food packaging

One of its biggest hazards of this type of fast food packaging is that when the temperature of food exceeds 65 degrees, it will release toxic substances such as bisphenol A and it will seep into your food.

In addition, poor quality plastic disposable foam fast food packaging (polypropylene that is not fully polymerized) has residual dimers and trimers. They are bad for our health.

How to reduce the risks

In order to avoid food packaging problems, when you need to package hot food, choosing the right type of packaging.

Another important thing is that be sure to check the printed date and quality and safety inspection signs on the outside of the packaging.

If the printed font is neat or clear, and there are quality and safety signs, then it is generally qualified.

PP plastic fast food packaging

PP plastic fast food packaging is made of polypropylene.

Compared to the other type of Polypropylene this type of fast food packaging greater advantage is its ability to withstand high temperatures

General Appearance of PP plastic fast food packaging

This type of fast food packaging appearance is transparent, strong, non-toxic, and harmless.

The lockboxes are normally where we see this type of material (check the image below).

Paper of fast food packaging:

This type of paper packaging is normally seen in this kind of packaging:

1.Paper box

2.Paper bowl

The raw material of paper packaging is more commonly known as kraft paper packaging, but that is not the only version. There a 5 types of paper packaging listed below:

Plant fiber:

Its raw materials are crop fibers such as rice straw, wheat straw, bagasse, and chaff. Therefore, such products are competitive in price. Moreover, the discarded plant fiber-fast food packaging can be degraded which can cultivate fertile soil. You can also collect them for livestock feed

Kraft

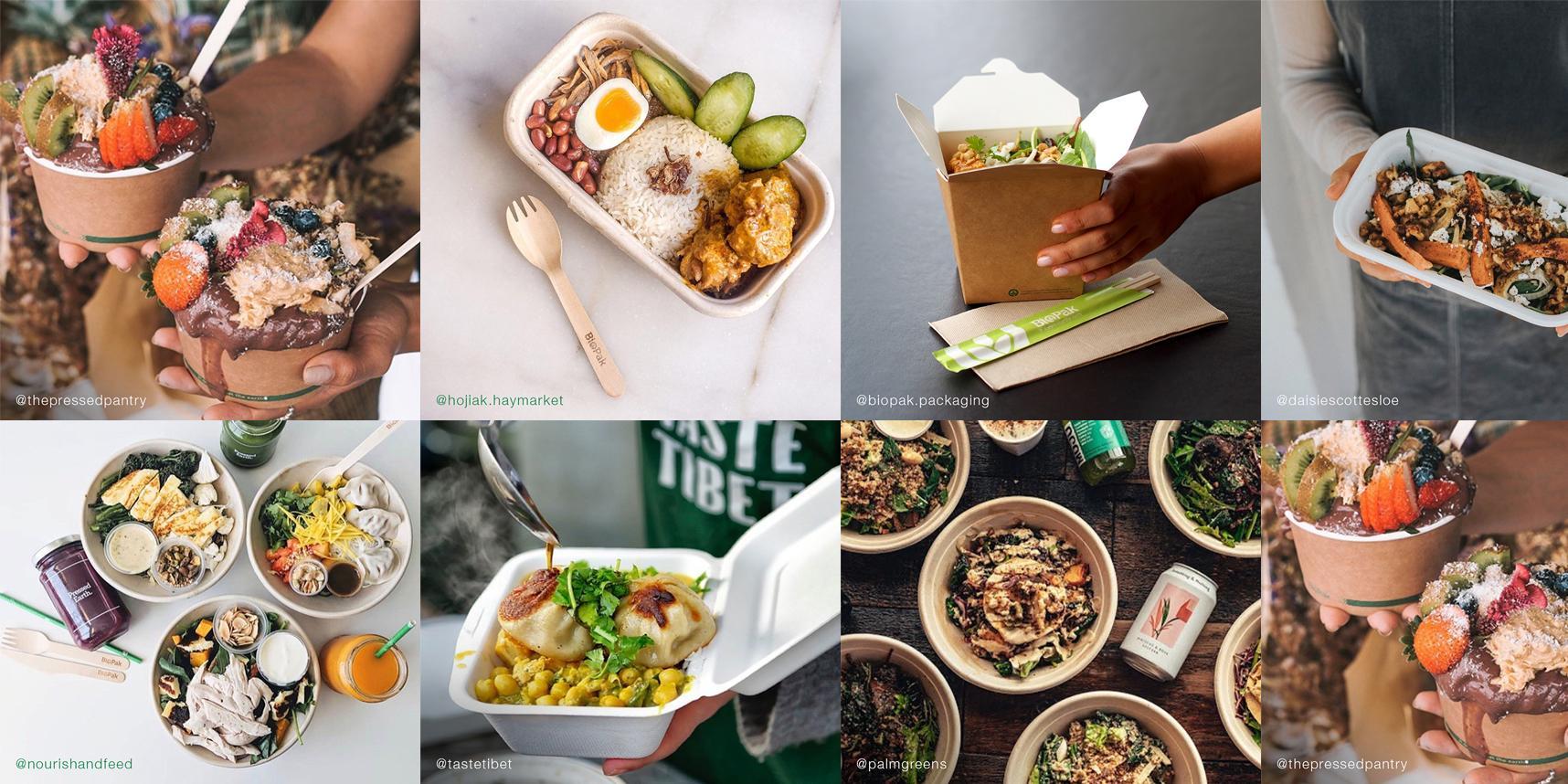

Natural Kraft packaging is very suitable for fast-food containers, because they are 100% recyclable, and many are made from recycled Kraft paper. Food packaging is a large volume being consumed every day, so if we use plastic containers for food packaging, rather than recyclable paper containers, it would cause very serious pollution to our environment. Thus people tend to use eco-friendly Kraft paper food box packaging today.

Composite paper bag

There are usually two or more layers of material together. Common materials include DAO: BOPP (light), MOPP (dumb), yellow, white and Kraft paper.

Nylon, paper, PET,VMPET(aluminum plated PET), PVDC, NY,AL(pure aluminum), CPP,RCPP (cooking CPP), PE,VMCPP (aluminum plated CPP)

Nylon, paper, PET, VMPET(aluminum plated PET), PVDC, NY, AL(pure aluminum), CPP, RCPP (cooking CPP), PE, VMCPP (aluminum plated CPP)Special paperboard for disposable packaging mainly made of straw pulp:

Use chemical additives to improve the quality of straw pulp to optimize application technology to ensure that its performance is close to the physical properties of wood pulp. At the same time, it can further reduce the production cost of tableware cardboard, and recycled paper, and alleviate the increasingly tense problem of pulp raw materials.

Pulp molding products:

Pulp molding is a three-dimensional papermaking technology. Their certain shapes are molded by a special mold on a molding machine. In this process, the raw material is waste paper.

However, all these types of paper packaging have a similar manufacturing process generally following these steps:

1.First at first, use stamping and forming tools to perform compression.

2.Second, map the chemical additives on the surface. This chemical agent can prevent water seepage.

Advantages of Paper packaging for Fast food industries

There are a few advantages of using paper packaging in the fast food industry such as:

# non-toxic

Packaging is most often bleached and dyed using chemicals that are harmful not only to the environment but to those handling the product as well.

Look for natural, nontoxic dyes like soy instead of traditional petroleum-based ink. It’s also much easier to recycle paper that’s been produced with straw or soy.

# Convenient

You can overlap them. That means they are convenient for transportation.

The need for convenience has had a big impact on restaurant delivery. Customers can order and eat food while on the road, or purchase food in the safety and comfort of their own home without having to cook or wash dishes.

This means that you should consider convenience when designing food delivery packaging. It should be light, easy to carry, and resealable (so you don’t need to eat in a single gulp).

For example, if you are a restaurant specializing in noodles, the takeout shop may have a handy handle on the top. Or, if you’re fixated on sandwiches, do it the way Eat&Go does, and offer accordion delivery tubes that get smaller and smaller as you eat. The end result is something to put in a customer’s pocket.

You can recycle them and you can fully utilize the resources by that. This also shows good economic and social benefits

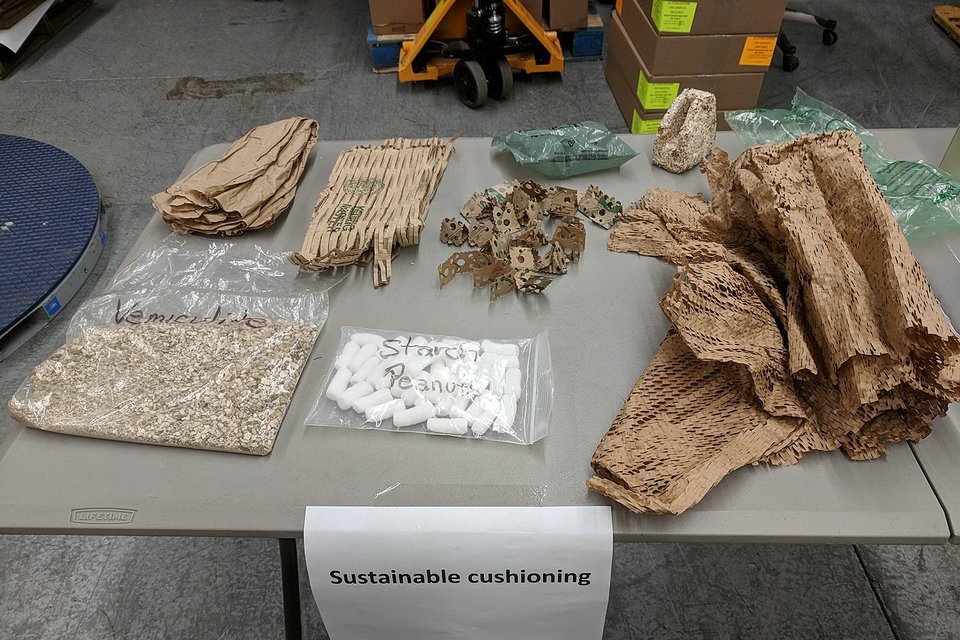

Biodegradable packaging

Biodegradable materials are polymer materials that can undergo chemical, biological, or physical degradation or enzymatic hydrolysis under the action of microorganisms that exist in nature such as bacteria, fungi, and algae. The most desirable biodegradable bio-materials are obtained from renewable resources. Once degraded, it can be reused by organisms. The best products are carbon dioxide and water so that the production and use of this material can be incorporated into the natural cycle.

Australian regulations in regards to bio degradable food packaging

In order to regulate controlled composting degradable materials entering the Australian market, the Australian Standards Committee established the corresponding standard: AS 4736 “Biodegradable Plastics-Biodegradable Plastics Suitable for Composting or Other Biological Treatments”

This standard is based on the European standard En 13432, and in addition to the Eco-toxicological performance requirements, an earthworm Eco-toxicological test has been added.

The specific requirements are:

- Chemical substance restriction: stipulate the minimum content of organic substances, heavy metals, and fluorine in controlled composting materials.

- Biodegradability: It is stipulated that more than 90% of controllable composting materials must be finally converted into carbon dioxide, water, and minerals in the longest month under aerobic composting conditions.

- Disintegration performance: It is stipulated that the controllable composting material must be disintegrated into more than 90% of the fragments that can pass through the 22mm screen within 12 weeks under aerobic composting conditions.

- Eco-toxicological performance: After the introduction of the compost decomposition material of the controllable compost degradation material, the selected plants can achieve more than 90% of the original survival rate and biological characteristics. At the same time, it must meet the requirements of earthworms when introducing the compost decomposition material of the controllable compost degradation material, reaching more than 90% of the original survival rate and biological characteristics.

The Australian market trend towards bio-degradable packaging

Retailers encourage customers to adopt biodegradable packaging. So they use the bags and fast-food packaging made of biodegradable material actively. But the regular plastic doesn’t biodegrade in a short time.

That is the reason why we have to landfill it. As environmental awareness growing, the compound annual growth rate of the global biodegradable packaging market will be close to 11%.

Materials used for Fast food Biodegradable packaging

Plastic is the main component of degradable fast-food packaging. However, sometimes people will add photo-sensitization or starch.

There are microbial enzymes in the natural environment.

The degradable fast food packaging will decompose into carbon dioxide and water under its action.

Advantages of using Biodegradable packaging in the fast food market

Down below are the advantages of using biodegradable packaging

- Environmental-friendly:we can reduce white pollution by using biodegradable packaging.

- Good properties:The raw material of biodegradable packaging is starch. For its longevity, it is better than packaging made of other materials. Another advantage is that its cost is lower than other materials.

- Mufti-functional:Customers can customize the size of bio-gradable packaging and print your brand and slogan on it. It can perform well for all kinds of fast food.

Fast food packaging requirements

In accordance with Australian regulations for fast food packaging your packaging needs to meet the following minimum standards:

- Any packaging and any “things or materials in contact with food in the packaging” shall not be swallowed or obstruct any diet or respiratory tract. If they get into the mouth by mistake, they may cause harm, distress.

- Food manufacturers must ensure that packaging that comes into contact with food does not cause the food to exceed the allowable content of metals, non-metals, or natural poisons.

- The packaging manufacturer or supplier shall ensure that any substances used in the packaging will not affect the safety and applicability of the food in contact.

- Australian standards directly reference the food contact regulations in the US Code of Federal Regulations and the European Commission’s directives. It notes that new plastic materials must meet the requirements for food contact polymers in these jurisdictions.

- Merchants can use recycled and reused materials for food packaging applications. However, the premise is that they are suitable for the intended use and will not contaminate food.

- Australian Standard 3.2.2 (“Food Safety Practices and General Requirements”) requires food companies to use packaging “suitable for their intended use”. They can only use materials that are unlikely to contaminate food. On this premise, it is ensured that the food is not contaminated during the packaging process.

The requirements of Australia for food contact substances depend on their intended function. Meanwhile, packaging must be safe and need to meet the limited regulations regarding chemical migration.

Australia and New Zealand’s requirements for food contact substances depend on their intended function. Meanwhile, packaging must be safe and comply with limited regulations regarding chemical migration. You need to continue to monitor the current regulatory framework for the risk of chemicals migrating from packaging to food.

The packaging must have a tag indicating the country in which it was manufactured. All the packaging should have a sign to show how much they can hold. If they have the inner packaging, you need to add a tag to show the net capacity of the inner packaging.

The tags on the packaging should be English. They must be clear and unfading. Regarding their position, the customers can see them easily. For their font, it cannot less than 1.5mm and their size should be the same. Besides, the color of the tag should be different from the background color of the packaging so that customers can tell them easily.

There are also prohibited materials. They are hay chaff, second-hand fruit, and vegetable cartons.

The first thing you need to know when choosing a fast-food carton or box for your company is that the design of these items will be one of the first things customers will see when they learn about your brand. Your customers will use the pictures and colors on the package to determine how they feel about your company – therefore, it’s important to get the right pictures in the first place.

You need to add IPPC logo on the wooden shipping box when export fast food packaging to Austral

There are two wooden material you can choose. They are fumigation and fumigation free.

Among them, solid wood material need to have the fumigation certification. The following countries have this certification:

- America

- Canada

- European union

- Japan

- Australia

For the fumigation free types, there are OSB board, plywood, particle board, fiberboard, etc., composite board, recycled board which go through high temperature and high pressure treatment.

Otherwise,you have to destroy your goods.

If the wooden shipping boxes have bark, worm eyes, moldy, or they are damp, you need to shovel the bark. For the worm eyes problem, you need to change the boxes.

How to choose the best fast food packaging

With the ever-increasing size of the fast-food industry and the global trend of more and more health/world conscious society, the demands for better quality packaging have never been greater.

So, what kind of packaging do we need to choose to increase the customer’s repurchase rate?

The functionality of fast food packaging

Better quality packaging creates a better experience for the customer and the better the experience the more likely they will repurchase from you again. Prime examples of this type of packaging are heat preservation, leak-proof and easy to carry

Case study: Mcdonalds fast food packaging

The old McDonald’s packaging vs the new image.

You can see why McDonald’s designed a separate take-out packaging bag. Customers can tear off the upper part of the bag, and the lower part of the bag becomes a small dinner plate creating a much better fast-food packaging experience.

Picture reference from: Bing.com

Things to consider when purchasing fast food packaging

In addition to the case study, we recommend considering the following factors when purchasing your food packaging.

– It’s healthy for you?

We know high-temperature hot oil in contact with low-quality plastics will produce substances harmful to the human body. Thus, consider more about whether this fast-food packaging is safe or not?

– Is it material is environmentally friendly?

– Whether the packaging chooses by the family is safe?

However, for business, you need to consider whether your packaging suits the fast food for what your selling? You need to think from both design and function.

# Whether it is easy to deform:

When choosing fast-packaging, you need to pay attention to the categories that can easily be squeezed and deformed to affect the taste. Such as cakes and desserts.

#Whether it is resistant to high temperature:

For example, you cannot use PET packaging to put high-temperature soups and hot-fried dishes. Otherwise, the PET packaging will melt easily with a peculiar smell.

# Is the airtightness good or not:

Many environmentally friendly materials have good textures and natural materials. However, their sealing performance is not high enough. Therefore, if the merchant uses it to serve dishes with juice, it may easy to spill.

In general, these factors have become the primary considerations for merchants in the choice of fast-food packaging.

This is a custom heading element.

– First, the practical function of fast-food packaging. Fast-food packaging is used to hold food. We must try to ensure that the taste of the food is the same as the dining experience. The packaging chosen by the merchant is insulated, breathable, leak-proof, and tight.

Besides, the high-temperature hot oil contacts inferior plastics to produce harmful substances to the human body, and whether the packaging chosen by the merchants is safe and eco-friendly, are the primary considerations for the supplier when choosing fast-food packaging.

– Second, fast-food packaging cost is the most concerned factor for most supplier. Many brand chains have a strict cost budget system, which is basically controlled within 5% of the average customer unit price.

If it goes beyond this range, it will increase the cost of fast food. The gross profit of the merchant will be greatly affected. Suppliers may try to improve user experience as much as possible based on cost budgets. Fast-food packaging can neither pursue high-end or simple packaging to excessively control costs. However, fast-food packaging input costs must be tailored, that is, the costs must match the per-customer price of dishes.

– Third, the appearance design of fast-food packaging, reasonable color matching, fashionable packaging style, attractive fast-food packaging shape, personalized copy writing, etc., these factors have a great effect on improving the consumer experience.

Catering fast-food businesses brand, which can have an overall understanding of the fast-food brand on the market, so that people can be based on customer unit prices, dish types, store positioning, and various packaging materials and price, to choose the packaging that suits their fast-food shop types.

If your businesses focus on cost performance, such as burger set meals, Pizza specials, and low-priced set meal series, the key factor that attracts users is the price of the dishes. At this time, the choice of fast-food packaging should be low-cost, simple, and practical. No need to blindly imitate other businesses. Choose to use high-cost kraft paper or non-woven handbags.

The cost is too high, which reduces the actual profit of the store. However, you can also consider using some low-priced packaging products, including printed store names, self-adhesive labels for store promotion, waist seals, etc., which to a certain extent also helps the store to shape the brand image and reasonably control the fast-food packaging cost.

Creative Examples of Fast Food Packaging

In general, reasonable color matching, fashionable packaging style, attractive take-out packaging style, and personalized copywriting all play a great role in enhancing consumer experience.

Here are sever case about some creative examples[1] of fast-food packaging

1. EDIBLE CUPS

KFC in Britain is experimenting with a cup that you can eat after drinking your coffee. The cup is made out of a wafer and lined in sugar paper and white chocolate. The company believes that this interesting new packaging will appeal to environmentally conscious customers.

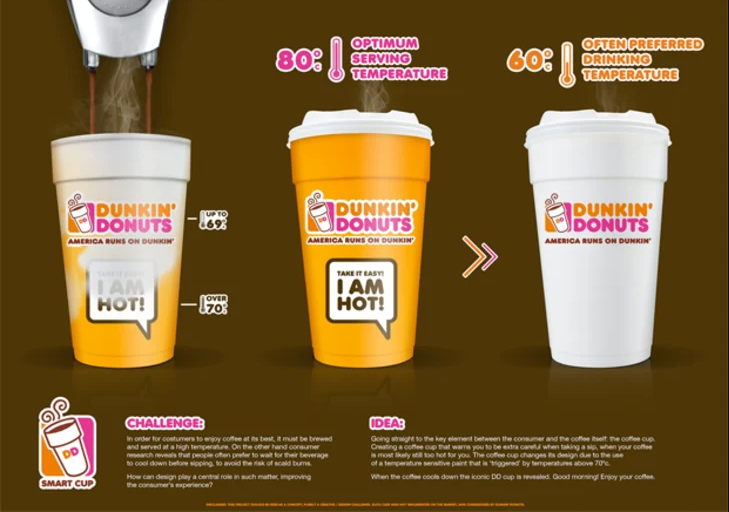

2.HEAT ALERT

Netherlands-based designer Tiago Pinto doesn’t want you to burn your mouth. That’s why he created a concept for Dunkin Donuts cups that alerts drinkers when their beverage is too hot. Hot cups are bright orange and say “I am hot!” but turn white once they’ve cooled to a safe temperature. This hasn’t been adopted yet, but we hope it is—it would really help keep us from missing the small window between scalding and lukewarm coffee.

3. SHOWTIME

Pizza Hut knows that pizza and movies are a great combination, so this year they created a pizza box that doubles as a projector. All you need is the box and a smartphone to turn any place into a mini-movie theater.

4. TEXT ON YOUR TRAY

KFC Germany has learned that texting with greasy fingers can be a real drag. To help out their oily patrons, they lined their trays with disposable Bluetooth keyboards instead of paper for a week in May. The plan seemed a little harebrained, but it worked—geolocated social interaction at the restaurants increased dramatically.

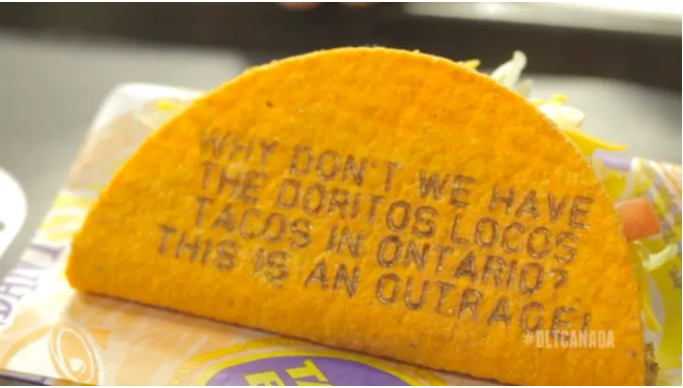

5. EAT YOUR TWEETS

Remember to watch what you tweet at Taco Bell because they might shame you with tacos. When the fast-food joint brought their Doritos Locos Tacos to Canada in 2013, their first action was to make the impatient complainers eat their words—literally. Those particular tweeters were invited to a “special fan event” and asked to eat tacos with their angry tweets printed on the side of the shell.

Fast food packaging in sustainable trends

America’s fast-food culture is hurting more than our waistlines. With its grab-and-go, overly packaged food stuffed with unnecessary condiments, fast food outlets are the primary source of urban litter and a significant hurdle to local communities’ waste diversion goals.

Therefore, convenience, practicality, and sustainability are all important when it comes to creating any incredible fast-food packaging. However, when you’re serving fast food, these three things become even more crucial.

To help you make the right impression with your fast food packaging, why there is so important to be more sustainable? And how fast food players take tentative steps towards sustainable packaging.

Trends of packaging pollution in the fast food industry

Litter characterization studies across the world have recognized fast-food restaurants as the primary identifiable source of urban litter. The most abundant type of non-cigarette litter is fast food packaging such as foamed polystyrene. This foamed plastic, a staple of fast-food restaurants, becomes a permanent fixture in our environment when littered. Easily traveling through gutters and storm drains, it eventually reaches the ocean. Indeed, plastics from urban runoff is the largest source of marine debris.[2]

Modern food packaging offers a way to make food safe, reliable, quality safe, and clean. Unfortunately, most food packaging is designed for single-use and is not recycled. On the contrary, the packaging is thrown away and litter is often left on our waterways. The United Nations has declared plastic pollution in the oceans a “planetary crisis” because so much food packaging, especially plastic, has become blocked in waterways. This is not just a human problem, but a problem for all aquatic life. Food packaging has other effects on the environment, including on our air and soil.

While it is difficult to find unpackaged food, there are real opportunities to choose packaging that is less harmful to animals, people, and the environment.

Furthermore, fast food restaurants are a drag on local communities’ waste diversion rates. Currently, less than 35% of fast food stores’ waste is diverted from landfills, the vast majority of which is cardboard. Very little food packaging and almost no fast food plastic are currently diverted from landfills. This low diversion rate is surprising considering the vast majority of restaurant waste is not plastic–its main litter culprit–but rather paper, a perfectly recyclable resource. A study of fast food waste in American found that up to 85% of the waste thrown out by fast-food chains could have been recycled or composted

The problem of fast food is not insurmountable. Like many areas of waste generation, a few simple, economical changes in the way the fast-food industry handles its waste could change what currently is a major source of unrecyclable, permanent litter to a model for other businesses.

Here we are, a new suggestion provides a roadmap for fast food companies on how to reduce their packaging footprint, if you need more ideas, the article down below may help you a lot!

# Greener fast food packaging can be good for the corporate bottom line.

Moving through the various attributes we identified there are numerous opportunities for companies to save money. Indirectly, being green is good for the corporate brand and can increase loyalty and customer base. More directly, by reducing the overall use of fast food packaging you save money in material costs and if you add to that smarter shipping, a company can save money on transportation costs. If you encourage re-use, you use less packaging, which saves money and increasing in-store recycling, individual restaurants and chains can cash in by selling those materials to recycling facilities.

# First step to fast-food company – A ECO-friendly policy

The first step is to develop an environmental packaging policy. Some of the key issues we identified in the report and work to develop buy-in at all levels with the company as well as collaborate with environmental, community, and academic experts that can help create the roadmap to greener packaging.

Next comes the heavy lifting of looking across your supply chain and working with suppliers to reduce the overall material use, increase the amount of recycled fiber, and eliminate all controversial sources of fiber.

# Customers can help persuade fast food companies to take action

For customers, there are a number of easy ways to make a difference. When buying fast food, ask for less packaging for your order and ask the manager to work to green the restaurant’s packaging. If possible, bring your own mug or to-go container to eliminate the need for new paper, styrofoam, or plastic packaging. If you are feeling more passionate, plug into efforts from environmental organizations, like the Kentucky Fried Forests campaign, to make a difference in that way.

And of course, if you own or work at a restaurant or have friends that do, share this report with them so that all restaurants big and small can see how their packaging can be greener.[3]

Case study

#1 Burger King

Burger King is testing reusable packaging. And, they supervise customers to return these special whopper boxes, soda boxes, coffee cups.

Then they washed them and reused them. Moreover, they launched a pilot program through TerraCycle’s zero waste circular packaging service.

As long as the packaging remains intact, they will clean and disinfect it for reuse. During the COVID period, we have all seen the environmental impact of increased takeaway orders.

Therefore, this makes Burger King’s plan is particularly important.

During the period, they adopted the method of collecting a deposit, and when the consumer returned the package, the merchant would refund the deposit. These not only avoid PFAS in disposable fast-food packaging but also eliminate hundreds of millions of waste in landfills.

#2 McDonald

Two McDonald’s Canada restaurants will soon be testbeds for the company’s greener packaging initiatives, serving wooden cutlery, paper straws, and another recycling-friendly packaging.

The fast-food giant’s move is the latest in a wave of announcements from major chains pledging to reduce their reliance on plastic, but experts say the steps are small, often take a long time to expand nationally, and, if not properly planned, will ultimately have a negligible impact.

In 2020 summer, customers will see wooden cutlery and stir sticks, and paper straws, as well as receive their cold drinks in a cup without plastic coating and with lids made from wood fiber.

It’s part of the company’s commitment to source all of its guest packaging from “renewable, recycled or certified sources” and recycle all of it at each of its restaurants by 2025.

Recommendations for choosing fast food packaging

With the problem we have told, here are some recommendations for choosing fast food packaging. Packaging offers many benefits. To realize these benefits, you need to take the time to choose packaging that’s right for your business.

# Use a complete life cycle and supply chain approach

What is a complete life cycle and supply chain approach?

In short, a supply chain life can be separated into three stages: 1) formation, 2) operation, and 3) extinction.

Each step is critical to the next step, even extinction is critical to the next formation and the overall success for the supply chain and the overall continuity of the business.

How it relates to fast-food packaging?

Reduce overall packaging and improve efficiency.

Companies can reduce the impact of packaging by reducing the total amount of packaging. For example, we can start with the design of fast food packaging to reduce the required materials. This not only means less material consumption and fewer landfills, but it can also save the company a lot of money.

Increase the use of recycled fiber in food packaging

Throughout the past year, global media has repeatedly highlighted growing concerns over the environmental impact of packaging material. If we continue with the current linear business models – take-make-waste – insufficient raw material resources, and an increased amount of waste and its negative impact on the environment becomes a serious problem. Whether it is the plastic material, damage to the aquatic fauna, or the impact on the food chain, these topics resonate for each of us as a consumer. As packaging is really part of our everyday life, more efficient use of our resources is needed.

To act upon those concerns, some country government takes an action plan includes a comprehensive package of policy tools that promote recyclability of products. There are two different routes for recycling depending on how the packaging was used:

Organic recycling:

since the paper is biodegradable, fiber-based post-consumer packaging can be recycled organically in-home or industrial composting if it is contaminated with food waste. In this method, packaging biodegrades and eventually composts back into the earth.

Stream recycling:

If the food packaging is recyclable according to the recycling standard EN13430 and is not contaminated after use, it can be put in the standard paper recycling stream.

We live in an era where your customers aren’t just concerned about getting the best tasting product or buying your meal at the best price. Today’s consumers also want to know that their purchases are making the world a better place. That’s why it’s so important to ensure that wherever possible, environmentally friendly materials are used in packaging.

You can even print a recyclable label on the package to remind customers of your green nature.

The possibility of eliminating packaging completely is very small, the best practice is to increase the use of recycled fibers.

Moreover, the use of recycled fibers has many advantages.

First, this can significantly reduce forest destruction and carbon emissions. Second, it can reduce the use of chemicals, water, and energy.

However, the challenge now is to increase recycled fiber across the board. These include cups, buckets, and boxes.

Use FSC certified fiber paper packaging

What is FSC certified? Why is so important?

FSC forest certification is also called sustainable forest management certification, which is a system to promote sustainable forest management. It is referred to as forest certification and wood certification for short. The reason why it is carried out by an independent third party is to ensure the fairness and transparency of forest certification.

Social benefits are embodied in ensuring that the rights of all interested parties are respected and realized. The most significant economic effect brought by forest certification is to increase forest productivity, ensure the long-term supply of wood, stabilize forest management rights, strengthen basic management and environmental management of enterprises, maintain or increase market share, and produce differentiated products and products Premium, improve relations with various stakeholders, strengthen contact with managers, obtain priority in forest management, improve staff morale and ability, attract talents, improve the competitiveness and reputation of enterprise products in the international market, and obtain more Financial and technical support.

The creation of FSC forest certification stabilizes the company’s existing product market share and creates market access conditions for entering new markets. It also improves the forest management level of forest management units and promotes sustainable forest management. In addition, it has also achieved the goals of promoting the participation of all stakeholders, commercializing forest services, reducing investment risks, strengthening law enforcement, and strengthening law enforcement.

Forest certification is mainly manifested in three parts: environmental benefits, social benefits, and economic benefits.

In the environmental benefits, it protects endangered species and their living environment, biodiversity and its value, water resources, soil, unique and fragile ecosystems, and natural landscapes, etc., while maintaining the ecological function of the forest and the integrity of the ecosystem To promote sustainable forest management.

Although reducing the overall use of packaging and substantially increasing the content of recycled fiber is critical to the sustainability of packaging, some fibers may still come from forests.

Therefore, businesses must understand their supply chain. And they want to eliminate controversial and environmentally damaging packaging sources.

The best way to ensure this is to use paper certified by the Forest Stewardship Council (FSC), which is the only certification system widely recognized by the environment.

The development trend of fast food packaging

In the future, what are the development trends of fast food packaging?

We’ve talked about this in a lot more detail in our “Everything about takeaway packaging” article but we think there needs to be a special mention of edible fast-food packaging below.

Edible fast food packaging

– In Japan

A Japanese research institute uses new technology. They used bean dregs as raw materials to make nutritious and edible wrapping paper that melts when heated. The wrapping paper is suitable for packaging fast-food noodle seasonings. Therefore, people can eat together.

-In British

The British use carrot paper as a base material. Add appropriate thickeners, plasticizers, and water repellents to use the natural color of carrots. The edible color vegetable paper is made of cheap and good quality. Increase the appetite and appetite of consumers. Therefore, carrot paper is edible colored paper. Moreover, it has flexibility and water resistance.

– In America

Some Americans have made fast food packaging with wheat stalk fiber and starch in wheat kernels. Moreover, biological packaging materials have little pollution to the environment and are cheap to counterfeit. Besides, its packaging materials have a longer heat preservation period for food than the paper materials currently used.

The environment can be better protected by using such edible packaging. Moreover, this provides new uses for the vegetable deep processing industry. Besides, this can reduce the use of air-polluting materials such as polystyrene in fast food packaging.

The way to reduce the impact of consumer packaging is to make better choices when we buy and consume food. As consumers, our food choices affect how much packaging we use, as well as how much waste we create and recycle. While recycling helps minimize the amount of packaging going to landfills, there are some basic options that can eliminate the need for packaging at all.

Design of diversified fast food packaging

Nowadays, the cycle of a new product from development to market entry is getting shorter and shorter. At the same time, their packaging structures and forms have gradually diversified.

Sometimes, a product has to adapt to different regions and different consumer groups. At this time, it needs multiple forms of packaging. Therefore, from creativity, color, specifications, materials, and production methods, businesses have different requirements for it.

In general, future packaging will use a combination of existing packaging and packaging patterns.

Rather than conceiving from scratch like traditional packaging design, from scratch, reference and combination are the mainstream of future packaging design.

Colours and tastes of fast food packaging

The color design of fast food packaging should also be related to the taste of the food. Scientists, psychologists, and marketing experts have studied and mapped the links between colors and their effects on human emotions and behavior. According to packaging design creative strategist Jenn David Connolly, “color affects not only the consumer consciousness but also the subconscious mind,” so choosing the color of a product’s packaging is as important as choosing its ingredients.

Because the taste is sweet, salty, sour, bitter, and spicy, there is also a difference between strong and light.

Therefore, if the design of fast food packaging needs to show so much taste in the package, then the designer must express it perform the expression according to the above-mentioned methods and laws of human understanding of things.

Secondly, packaging patterns also have a certain impact on taste.

The different shapes and styles of pictures or illustrations on food packaging can also give consumers taste hints.

For example, round, semicircle, and oval decorative patterns make people feel warm, soft, and wet.

Depending on the product you intend to sell, you will need to ensure that the packaging company you work with provides the correct shape and size of packaging for your customers. For example, if you are going to sell hamburgers, you will need a hamburger box with enough space to hold enough toppings. If you are selling well-structured salads, you may need a lunch box with a window to attract customers.

You can use them for mild-tasting foods. Such as pastries, preserves, and even convenience foods, while the square and triangle patterns have the opposite designs. They feel cold, hard, crisp, and dry. As a result, patterns of these shapes are more suitable for puffed food, frozen food, dry goods, etc. than circular patterns.

The cases of fast food packaging

Burger King and McDonald’s have improved their packaging, and now there is a more concise and new attractive trend in graphic design. But more important than the paper in the Pubao, these companies began to pay more attention to reusable packaging in food.

Because although customers like the new look of the packaging paper, the company is becoming more natural to move forward in the future, and you bear the brunt of paper and plastic.

In the plastic survey conducted by Adweek and Harris Poll, 81% of customers said they were concerned about trash and pollution in fast food restaurants. Consider straws, bags, napkins, and yes, packaging.

Burger King recently launched a Czech reusable packaging program where customers can use and recycle containers and containers. Starbucks followed closely and may implement cup reuse and recycling programs in some places.

More and more restaurants have the same impulse.

Around the same time as Burger King, McDonald’s may have packaged its own reusable. Loop is the same reusable platform that launched reusable packaging in cooperation with Beijing. Later this year, it will fund the project plan with the British Golden Arch partners. .

From 2021, Burger King will reuse the packaging system instead of snack packaging for customers in selected cities. Within the scope of the “Good Restaurant Brand” program in New York, Portland, and Tokyo, providing a deposit allow you to purchase Whoppers, soft drinks, and coffee in a reusable form. Other brands, Kraft Heinz, are also aspects of TerraCycle Loop’s packaging service supplies project. This packaging recycling system can be tested together, play a synergistic effect, and share expertise and discoveries.

As with all foods, the food safety packaging of the product is also packaged. Only use the tried-and-tested circulatory cleaning system to clean, disinfect and hold reusable containers and containers to ensure the best standards of hygiene.

Burger King Investment Sustainable Development

The Loop fast food packaging test project is a combination of the sustainable development strategy of the fast-food chain. Wang has made a promise: Their goal is to use only renewable, recyclable, or certified fast food packaging by 2025 to continuously reduce carbon. Their waste management policy will also be improved: By 2025, this small restaurant will recycle 100% of the packaging of all its customers in the United States and Canada.

The entire food industry will become a “good restaurant brand” cooperation, which allows them to bring a huge leap in packaging products.

“I found a reusable solution that meets our standards while providing customers with the convenience measures they need in the circulatory system,” said Manton, Burger King Innovation and our global head of sustainable development. Summarized the concept behind this new project.

Burger King’s performance in the implementation of recycling reusable packaging: Unilever, Tesco, Tupperware, Haagen-Dazs, Beiersdorf, and many other companies rely on the reusable system of the American recycling company TerraCycle.

McDonald’s launches reusable cups

McDonald’s also hopes that more funds will be available for reusable solutions, and will start cooperating with TerraCycle in the UK in 2021. They will first introduce reusable hot drink cups. In Germany, ReCup plans to start operation in 2020. Some restaurants provide reusable coffee cups. Customers can return them after using them to get back the deposit they paid. Similar solutions are available in other markets, including the Philippines.

International packaging market forecast

In addition, according to the introduction of international packaging market experts, the development trend of food packaging is as follows:

-Aseptic packaging will use high-tech and new materials;

-Non-toxic packaging materials become safer;

-Large plastic containers and small and medium-sized plastic bottles will gradually replace glass products;

-Composite flexible packaging made of paper, aluminum foil, plastic film, etc., will be more up-scaled and multifunctional;

-Apply petrochemical products to manufacture auxiliary packaging materials for new packaging raw materials;

Conclusion

In general, fast food packaging has the following types:

- IDisposable foam plastic fast food packaging

- lPP plastic fast food packaging

- lPaper fast food packaging

- lDegradable fast food packaging

Moreover, they must meet hygiene requirements in Australian regulations. Among them, safety and non-toxicity are the most basic requirements.

When you choose fast food packaging, pay attention to the functionality of fast food packaging. In addition, fast food packaging for different purposes should be selected according to different types of food.

Of course, you still have to consider the cost and choose a fast-food package that is cost-effective and fits your own products.

Now we have a great demand for fast food packaging. However, we cannot ignore the problems.

Most oil-draining and waterproof fiber packaging contain PFAS, a toxic substance.

In order to avoid it, factories and businesses in the industry are making a lot of efforts to avoid using them.

About PeimePac

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our professional sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Network

With our teams in China and Australia working as one, we reduce inefficiency so that you deal with one streamlined team from manufacturing right to delivery.

Service support team located in Guangzhou, the manufacturing hub of China, providing rapid response, and local industry knowledge. Warehouse and 3PL network located in Sydney, to provide rapid distribution, and delivery to your customers.