Cosmetic tubes play a vital role in the packaging of numerous beauty products, encompassing an extensive range from lotions and creams to gels and serums. These tubes serve as indispensable tools for preserving the freshness and integrity of the products, shielding them from contamination. With an array of options available, including diverse shapes, sizes, and materials, they offer versatility and functionality.

Within the confines of this article, we will delve into the various classifications of cosmetic tubes and elucidate the advantages they offer. Furthermore, we will examine essential factors such as design considerations, labelling requirements, and customization potentials.

Continue reading to acquire a comprehensive understanding of the realm of cosmetic tubes and their significance in the beauty industry.

Laminated tube VS Co-extruded tube (PE tube)

A Wide Spectrum of Cosmetic Tubes: Exploring an Extensive Array of Choices

In the expansive market of tube packaging, a multitude of options caters to diverse applications. Among these alternatives, cosmetic tubes emerge as the prevailing choice. Fabricated from plastic, aluminum, or laminated materials, cosmetic tubes present an impressive assortment of shapes, sizes, and colors.

Their inherent versatility enables their utilization across a myriad of product categories, encompassing lip balm, lip gloss, mascara, foundation, and more. Furthermore, cosmetic tubes boast a range of noteworthy features that enhance their functionality. Notably, the integration of airless technology ensures the integrity of the enclosed product by establishing a reliable barrier against the infiltration of air and bacteria. Additionally, the incorporation of airless seals effectively prevents any untimely leakage.

Moreover, these tubes often incorporate additional attributes, such as anti-microbial coatings, which effectively impede bacterial growth on the tube’s surface. Simultaneously, tamper-resistant caps provide an additional layer of protection against unauthorized access, allowing only the intended user to access the product.

With an extensive selection of cosmetic tube options available, discovering the ideal match for your specific product becomes an effortless endeavor.

Distinguishing Laminated Tubes from Plastic Squeeze Tubes

When considering cosmetic packaging, it’s essential to understand the distinction between laminated tubes and plastic squeeze tubes. Plastic squeeze tubes possess several advantages such as being lightweight, portable, robust, and recyclable. They are easily squeezable, offer excellent processing capabilities, and allow for adaptable printing. These attributes make plastic tubes widely utilized in various applications, including:

- Face cleansing products, such as face cleansers.

- Skin care products, including eye creams, moisturizers, nutritional creams, face creams, and sunscreens.

- Beauty salon products, like shampoos, conditioners, and lipsticks.

- Other cosmetic packaging needs.

Let’s explore the different types of cosmetic squeeze tubes:

1. PE Plastic Tubes:

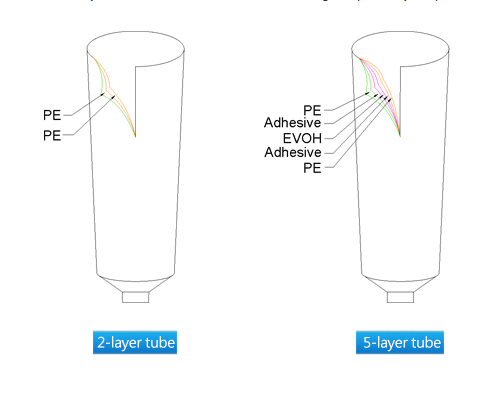

Plastic tubes can be crafted from LDPE (Low-density polyethylene), MDPE (Medium-density polyethylene), HDPE (High-density polyethylene), and EVOH (Ethylene Vinyl Alcohol Polymer). Manufactured through the extrusion process, plastic tubes are available as either mono-layered or multi-layered structures. A “sleeve” is produced from virgin resin and colorant using an extrusion line. The tube’s diameter and length are determined by the extrusion equipment. Once the sleeve is produced, the tube head is fitted using an automated heading machine. PE plastic tubes come in single-layer, double-layer, and five-layer variants. Five-layer cosmetic tubes (EVOH tubes/CO-EX tubes) incorporate EVOH, while single and double-layer tubes do not. Please refer to the accompanying image for the structure of a five-layer tube.

2. Laminated Cosmetic Tubes:

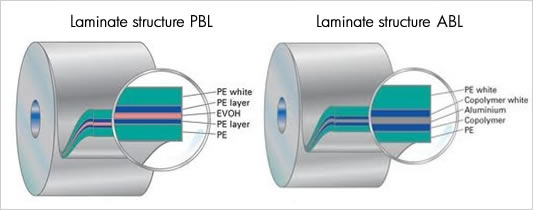

a) ABL Laminated Tubes: ABL tubes combine an environmentally friendly product with high-quality printing options. These tubes are ideal for holding various products, including liniment creams, makeup, essential oils, toothpaste, pharmaceuticals, and industrial items. ABL tubes are made by processing a sheet composed of aluminum and plastic through a co-extrusion compounding process. This sheet is then transformed into tubular packaging containers using a pipe-making machine. Designed primarily for the cosmetic industry, this process ensures hygiene and provides a barrier for performance requirements. The technology of ABL tubes continues to evolve.

b) PBL Laminated Tubes: PBL tubes are entirely composed of plastic and, like ABL tubes, offer an environmentally friendly solution with high-quality printing options. PBL tubes are easily recyclable, benefiting both the environment and clients. They find application in various industries, including lip gloss and other cosmetic products. PBL tubes provide a stable packaging platform and offer exceptional versatility. They exhibit unmatched clarity and artwork solutions, with the option of eight different printed colors. Moreover, the PBL’s structure retains the “memory” of plastic, which is a unique characteristic, even when compared to ABL tubes. The EVOH layer in PBL tubes protects the product from oxygen and prevents moisture and debris from entering the tubes.

Understanding the differences between laminated tubes and plastic squeeze tubes enables informed decision-making when it comes to selecting the appropriate packaging solution for cosmetic products.

PBL Cosmetic Laminated Tube versus ABL Cosmetic Laminated Tube

Customization Possibilities for Cosmetic Tubes

Personalizing your cosmetic containers opens up a world of possibilities, allowing you to create distinctive products that truly stand out. Cosmetic tubes offer a wide range of options, including diverse shapes, sizes, and colors, that can be enhanced through the addition of your brand name, logo, or slogan.

Choose the most suitable cap, nozzle, or pump to complement your product. The customization journey extends even further, as you can tailor the design of your tubes to create a truly unique aesthetic.

In addition to customization possibilities, cosmetic tubes offer versatility and multifunctionality with specialized heads and nozzles. These attributes make them suitable for a wide range of cosmetic products, from lip balms and eye creams to mascara and foundation. Tubes with wands, roller balls, sponge heads, twist-off caps, mascara brushes, lip applicator heads, and airless pumps cater to diverse application needs.

Moreover, a variety of decoration techniques can be employed to give your tube a unique and stylish appearance. Silkscreen and offset printing, foil stamping, spot UV print, translucent tubes, gradation colors, and pearlized and metallic finishes with different gloss or matte lacquers can all be utilized to add a personalized touch.

The options extend to the selection of caps and closures, available in various shapes, materials, colours, and finishes. Whether you prefer natural, white, coloured, PP, metal, or acrylic caps, you can further enhance their appearance with pearlized, glossy, matte, or metallic finishes. For a truly distinctive touch, custom caps with individualized designs can be created using private molds.

In summary, the customization possibilities for cosmetic tubes are extensive, offering a means to create attractive and informative packaging that sets your product apart in the market.

Advantages of Cosmetic Tubes

Beyond their apparent functionality, cosmetic tubes offer a host of benefits that elevate their appeal in the realm of beauty and hygiene products. Renowned for their ease of transportation and storage, these containers have garnered widespread popularity.

Furthermore, their exceptional customizability allows for the packaging of products in virtually any desired shape or size. This versatility renders cosmetic tubes suitable for a wide range of applications, spanning from body wash and shampoo to lotions and sunscreens.

Another remarkable benefit of cosmetic tubes lies in their environmental consciousness. Unlike conventional plastic containers, the majority of cosmetic tubes are crafted from renewable, recyclable materials such as polylactic acid, making them a sustainable choice. Moreover, their lightweight design facilitates convenient transportation, thereby reducing carbon emissions and minimizing one’s carbon footprint. Additionally, cosmetic tubes are recyclable, enabling a reduction in waste generation.

In essence, cosmetic tubes offer a harmonious blend of convenience, sustainability, and protection, rendering them an excellent packaging choice for beauty and hygiene products.

Laminated tubes

Considerations for Designing Cosmetic Tubes

In the realm of cosmetic container design, meticulous attention must be given to factors such as product size, shape, and material selection to ensure optimal protection and sustainability. The choice of a tube material plays a pivotal role in preserving product quality and safeguarding it against potential damage. Resilience to external factors should be a key consideration to ensure the product remains safe and secure.

The shape of the tube also merits careful consideration, as it influences both the product’s capacity and usability. The tube’s design should strike a balance between accommodating an appropriate product volume and facilitating ease of application. Moreover, the size of the tube holds significance, as it impacts the portability and convenience of the product.

Furthermore, the overall design of the cosmetic tube should not be overlooked. Elements such as color, texture, and shape contribute to the aesthetic appeal of both the tube and the enclosed product, potentially influencing customers’ purchasing decisions. Striking the right balance between eye-catching allure and functional practicality is paramount.

By thoughtfully considering these design aspects, an attractive and effective cosmetic tube can be created, aligning with the brand’s vision and captivating potential customers.

Conclusion

Primepac Packaging is an esteemed industry leader renowned for delivering cutting-edge and premium cosmetic tube packaging solutions. With a wealth of expertise and extensive experience, Primepac Packaging excels in creating innovative and captivating cosmetic tube designs that consistently exceed customer expectations. We are fully equipped to cater to your specific needs, offering a wide range of options including single layer, 5 layer, ABL, PBL, Airless tubes, and more.

Our comprehensive services encompass the seamless provision of diverse cosmetic tubes featuring multi-color printing, all conveniently delivered directly to your designated filling location. Meticulously manufactured using MDPE (Medium Density Polyethylene blends), our tubes offer the flexibility of single or multi-layer materials, expertly engineered to withstand the rigors of aggressive essential oils or chemicals.

In addition to our extensive product range, we leverage our many years expertise in plastic compatibility with various ingredients, providing a wealth of options for colors, caps, printing, and foil tamper-evident sealing. As part of our commitment to customer satisfaction, we also offer complimentary local delivery to your store, ensuring a seamless experience. It’s important to note that a minimum order quantity of 5,000 units per print is required.

Cosmetic tubes offer exceptional advantages for packaging your cosmetics, providing a diverse array of types, benefits, and design considerations while meeting labeling requirements and allowing for customization. In addition to their cost-effectiveness, these tubes can be precisely tailored to meet your unique requirements.

By embracing the power of appropriate packaging, you can effortlessly make a bold statement and distinguish yourself from competitors. Join us in embracing the future of packaging by transitioning to cosmetic tubes today.