Have you heard of airless bottles? They’re a game-changing product in the packaging industry! These containers have become all the rage because they offer superior protection and dispensing capabilities compared to traditional pump systems. Additionally, the airless bottles have an aesthetically premium appearance that makes them a compelling choice for many cosmetic brands. One of the best features of the airless bottles is that they protect the ingredient integrity, which is a crucial factor for skincare brands.

If you’re interested in learning more about airless pump bottles, you’re in luck! We’ve got an in-depth look at everything you need to know – from what they are and how they work, to the different types available and the benefits of using them. Join us on a journey where we explore the innovative world of packaging and discover why airless bottles are becoming the preferred choice for so many people.

Table of Content

- What Is Airless Pump Bottle?

- How Does Airless Pump BottleWork?

- The Components of Airless Pump Bottle

- Types of Airless Pump Bottle

- The Applications of Airless Pump Bottle

- The Key to A Successful Airless Pump Bottle Experience

- Unlocking the Benefits of Airless Pump Bottle

- Exploring the Endless Possibilities of Airless Pump Bottle

- Making the Switch to Airless Pump Bottle

What Is Airless Pump Bottle?

An airless bottle is a container designed to store and dispense liquids, utilizing a piston-type vacuum system as its core mechanism.

How Does Airless Pump Bottle Work?

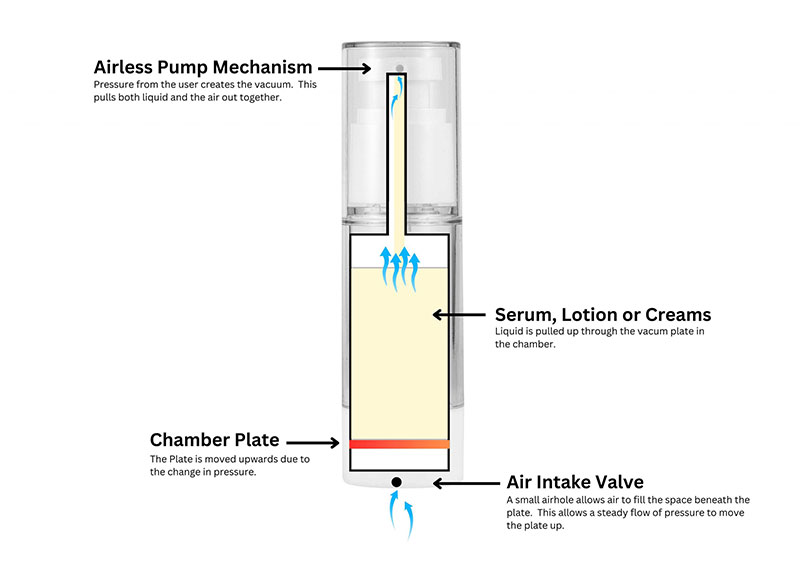

Within the bottle body, there is a piston situated at the base, creating a sealed space between itself and the dispensing nozzle located at the top. The liquid or material is stored within this enclosed space, and when the actuator is pressed, a slight vacuum is generated within the chamber. As a result, the piston is pushed upward by external atmospheric pressure, facilitating the controlled distribution of the stored material through the dispenser.

The key aspect of this technology lies in the precise interaction between the piston and the inner wall of the bottle. It is crucial that this fit is neither too tight nor too loose. If it’s too tight, the piston may become immobile, preventing the liquid from being pumped out. Conversely, if it’s too loose, there’s a risk of leakage. Consequently, the design of airless bottles is often influenced by the need for consistent and regular packaging shapes, such as circles or ellipses, to ensure the effectiveness of the piston-based vacuum system.

The Components of Airless Pump Bottle

Traditional dispensers with tubes have been around for ages, but airless pump bottles are revolutionizing the skincare industry. Instead of relying on tubes, they utilize a vacuum mechanism consisting of three vital components:

- Base Cap: This tiny hole allows air to enter the bottle, initiating the vacuum effect.

- Plate (or Disc): Inside the bottle, a plate supports your skincare product.

- Pump: The pump creates a vacuum effect, extracting the product when you press it.

Types of Airless Pump Bottle

- Twist-Up Airless Bottle: By twisting the bottle, the actuator is revealed, and users can then press down to dispense the desired amount of the product. Once done, they can simply turn the bottle in the opposite direction to conceal the pump.

- Airless Press Pump Bottle: Airless press pump bottles have a pump mechanism on the top that you press down to dispense the product. This action creates a vacuum that pushes the product upwards, preventing air from entering the container.

- Round Airless Bottle: Round airless bottles come in a traditional cylindrical shape. They are available in various sizes and are commonly used for a wide range of skincare and cosmetic products. They can have different dispensing mechanisms, such as twist-up or press pump.

- Square Airless Bottle: Square airless bottles have a square or rectangular shape instead of the traditional round design. They offer a unique and modern appearance and are often chosen for high-end cosmetic products.

- Dual Airless Chamber Bottle: Dual airless chamber bottles consist of two separate chambers within the same bottle. These chambers can be used to store two different products, which are typically dispensed simultaneously or separately through different dispensing mechanisms. For example, one chamber could hold a moisturizer, and the other could contain a serum, both protected from air exposure until use.

image from Pinterest

Explore the diverse range of airless pump bottle types with Primepac’s expert guidance. We assist in navigating the options available, ensuring you find the perfect fit for your product.

The Applications of Airless Bottle

- Face creams

- Lotions

- Serums

- Organic creams

- Foundations

- Moisturizers

- Other skincare products

The Key to A Successful Airless Pump Bottle Experience

By now, you should have a good understanding of pump dispenser bottles and how they work. However, there are crucial factors to ensure a seamless experience.

- Clear the Airway: The air needs a pathway through the base cap to push the piston. A blocked air hole due to stickers or obstructions can disrupt the bottle’s performance. Keeping it clear is vital for a successful airless pump bottle.

- Full Filling: Adequate filling is essential. When the pump dispenses the product, it initiates piston movement through suction. If the bottle is underfilled and the pump can’t cover the formula properly, incomplete suction can lead to a subpar user experience.

- Bubbly Filling: Air bubbles in the formula can create issues similar to underfilling. Ensuring a bubble-free formulation during filling is crucial to maintain proper functionality.

- Pre-Production Testing: Before mass production, conduct a thorough test to ensure your product is suitable for airless packaging. Formula thickness matters, as highly viscous formulations may not smoothly replace dispensed space, while thin formulas may lead to leakage.

Unlocking the Benefits of Airless Pump Bottle

- Vacuum dispensing effect reduces product wastage.

- Provides a luxurious packaging solution.

- Single, Dual, or Triple airless bottles accommodate multiple cosmetic solutions in one container.

- Liquid contents do not come into contact with metal springs, preventing oxidation issues.

- Eliminates back-flow problems, ensuring longer shelf life for contents.

- Restricts airflow, preserving ingredient integrity and effectiveness.

- Enhances shelf life and product integrity by preventing contamination.

image from Pinterest

Exploring the Endless Possibilities of Airless Pump Bottle

The Material Options for Airless Pump Bottle

- AS

- PP

- ABS

- Glass

- Aluminum

- Frosted Glass

- Acrylic

- Sliver/Gold Metal

Determining the ideal material for your skincare product’s airless pump bottle can be a pivotal decision. At Primepac, our experts excel in navigating the nuances of AS, PP, ABS, Glass, Aluminum, Frosted Glass, Acrylic, and Silver/Gold Metal. Reach out to us for tailored guidance that aligns your product’s unique requirements with the optimal material choice, ensuring your packaging reflects both quality and brand essence.

The Decoration Options for Airless Pump Bottle

- Matte spray coating: Matte spray coating provides a smooth, non-reflective finish to the bottle’s surface, giving it a modern and sophisticated look. It can also provide a tactile sensation, making the bottle feel more luxurious.

- Spray coating: Spray coating involves applying a thin layer of paint or coating to the bottle’s surface. This can be done in various colors and finishes, including glossy or satin. It adds a layer of protection to the bottle and can be customized to match brand colors.

- Metalization: Metalization is a process where a thin layer of metallic material, such as gold or silver, is applied to the surface of the bottle. It creates a reflective, shiny appearance, adding a touch of elegance and luxury to the packaging.

- Hot stamping: Hot stamping is a method of transferring a foil or metallic finish onto the surface of the bottle using heat and pressure. It’s often used for adding logos, brand names, or decorative elements in metallic or holographic colors. Hot stamping can create eye-catching accents.

- Silkscreen: Silkscreen printing involves applying ink through a mesh screen onto the bottle’s surface. It’s a versatile option for adding intricate designs, patterns, or detailed logos. Silkscreen printing allows for precise color matching and fine details.

- Screen print: Screen printing is similar to silkscreen printing and is used to transfer ink onto the bottle’s surface through a stencil. It’s suitable for bold and vibrant designs, and it can cover a larger area with a consistent finish.

Making the Switch to Airless Pump Bottles

Are you prepared to embrace the benefits of airless pump bottles for your skincare brand? The transition to airless pump bottles can significantly reduce product contamination, preserve freshness, and eliminate the need for chemical preservatives, while also providing precise dosing, minimal wastage, and an eco-friendly approach to skincare packaging.

At PrimePac, we are committed to magnifying your customers’ skincare experience through our innovative airless pump bottles. Our products are specifically designed to offer the best in skincare preservation and application, ensuring that your clients receive the highest quality skincare possible.

Join the skincare revolution today and acquaint yourself with our airless pump products. With our products, you can bid farewell to wasted products and embrace fresher, more efficient skincare packaging solutions. Do not miss out on this opportunity to improve your brand’s image.